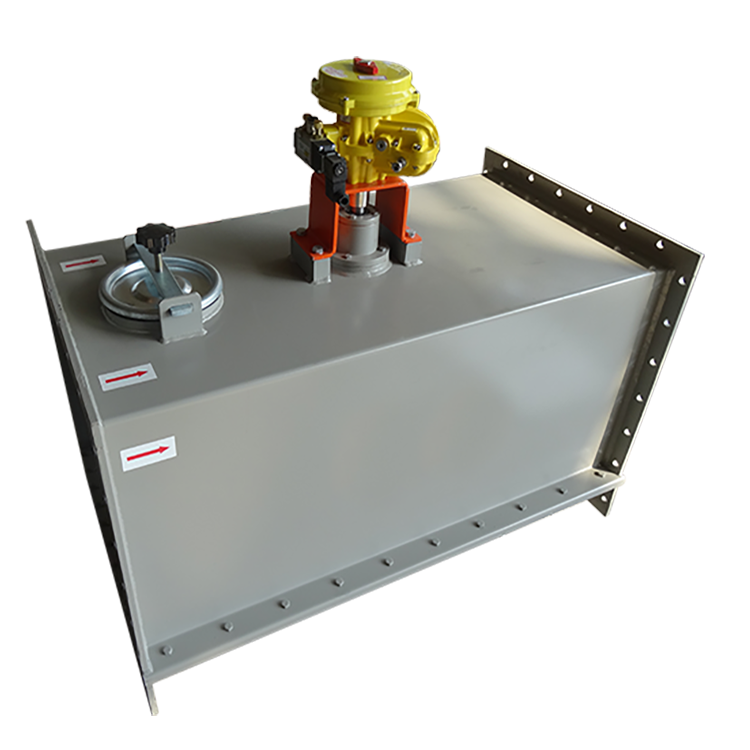

Pneumatic actuators differ from other actuator types as they work with compressed air. Actuators are basically driven by air, electricity or liquid. Accordingly, they are named electric, hydraulic and pneumatic. Pneumatics are distinguished among themselves. Some pneumatic actuators are cylinders and some are piston types. On the other hand, some of the pneumatic actuators have a spring inside and they work thanks to this spring.

These types of actuators are called single-acting pneumatic actuators. Some pneumatic actuators, on the other hand, work with compressed air supplied at different inlets. Compressed air from one inlet operates these actuators, while the air given from the other inlet makes them shut off. The most important features that distinguish pneumatic actuators from others are that they can be opened and closed easily and this situation provides an advantage, especially in emergency situations.

Other Advantages of Pneumatic Actuators

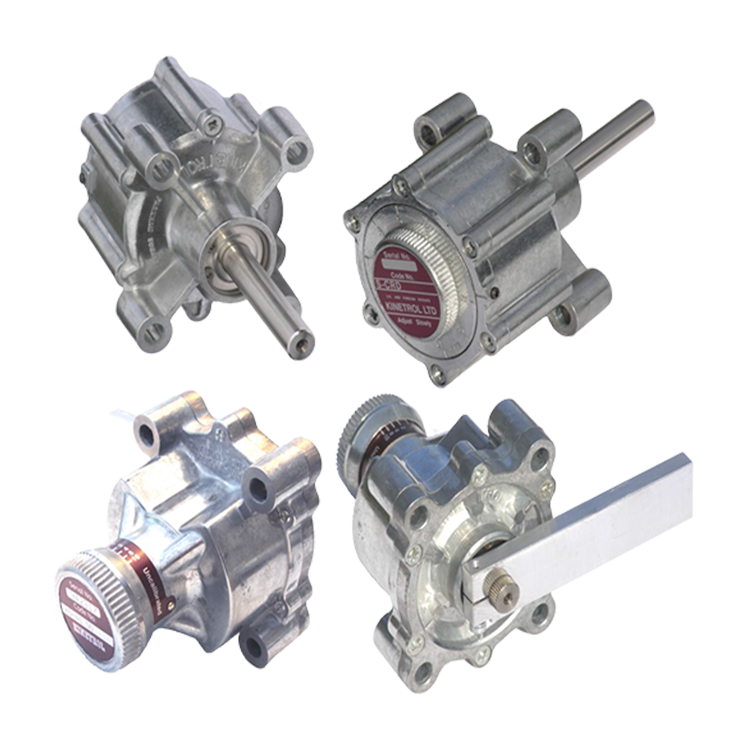

Pneumatic actuators, which have a light structure, can be operated at a much lower cost and much more efficiently than others. They can work very safely in an explosive atmosphere. On the other hand, it costs a little higher in terms of installation, but considering the operating cost, this is not evaluated as a disadvantage. They are among the most preferred actuators in the chemical industry as they can operate with a very high torque speed.

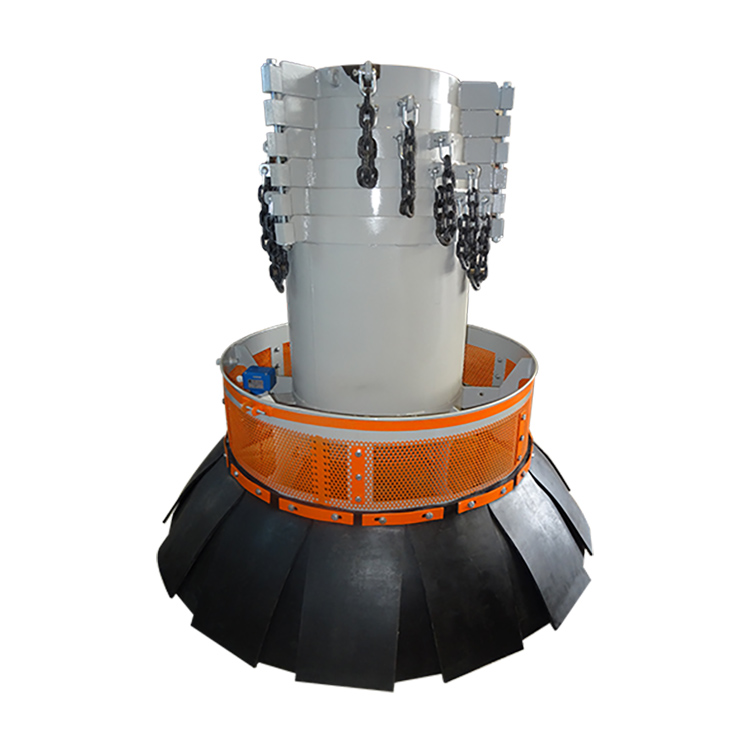

Rotary Pneumatic Actuator

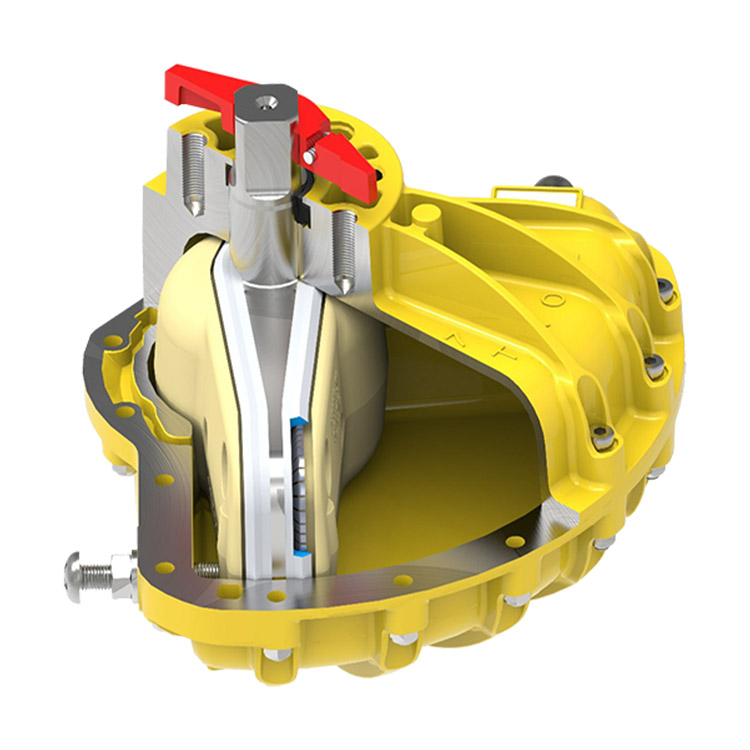

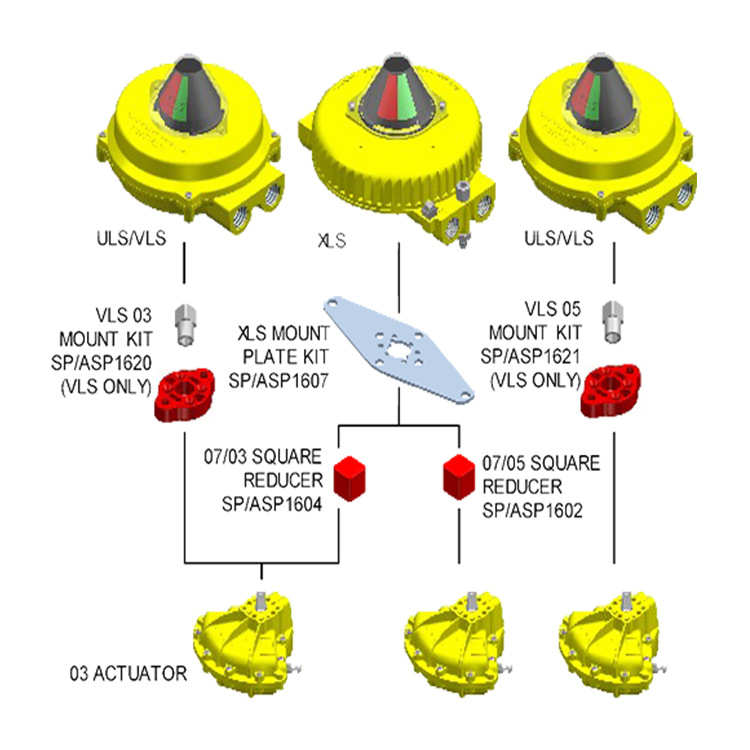

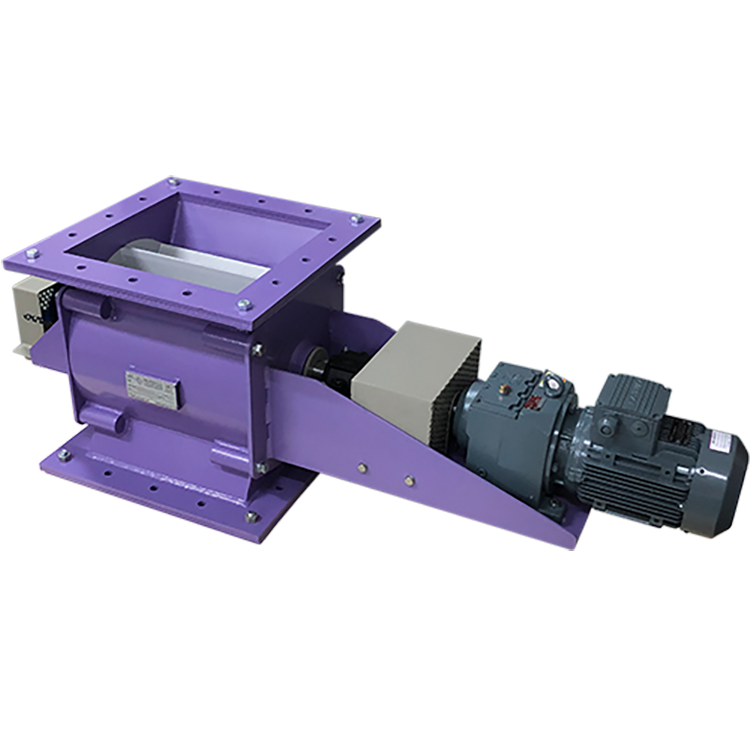

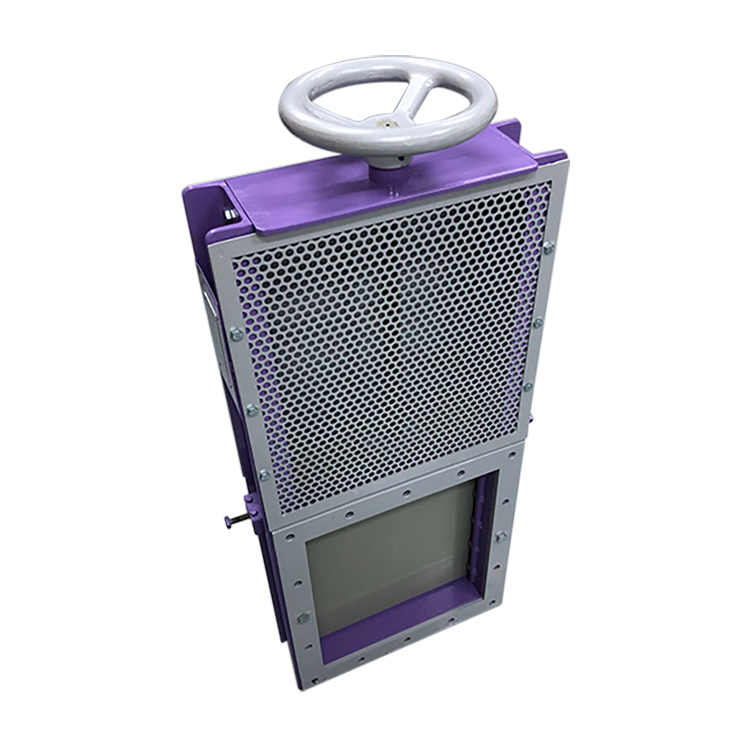

Pneumatic actuators can be mounted on different valves such as butterfly or ball valves enable these valves to operate with compressed air. The way of pneumatic actuators open and close valves are also a basic feature that determines them. Some application by controlling the opening and closing ,called on-off, and activates the valves. These are called pneumatic actuators operating as on-off control mode.

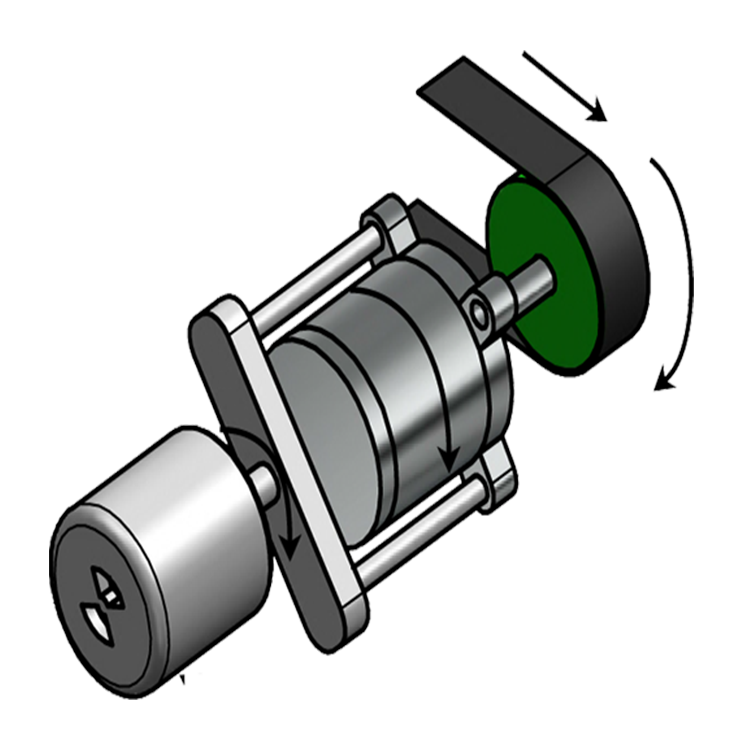

Others are rotary pneumatic actuators. They work according to the ratio of supplied compressed air. These pneumatic actuators, which work as modulating control, are activated through positioners. Usually, these are in degrees and work with 90 degrees of rotation. They are activated according to the ratio of the given air pressure and operate the system with torque as much as the application needs. Rotary pneumatic actuators are extremely advantageous in terms of reliability and performance. Additionally, rotary type pneumatic actuators can also be operated AS on-off. The important point is that they work 90 degrees.

TR

TR