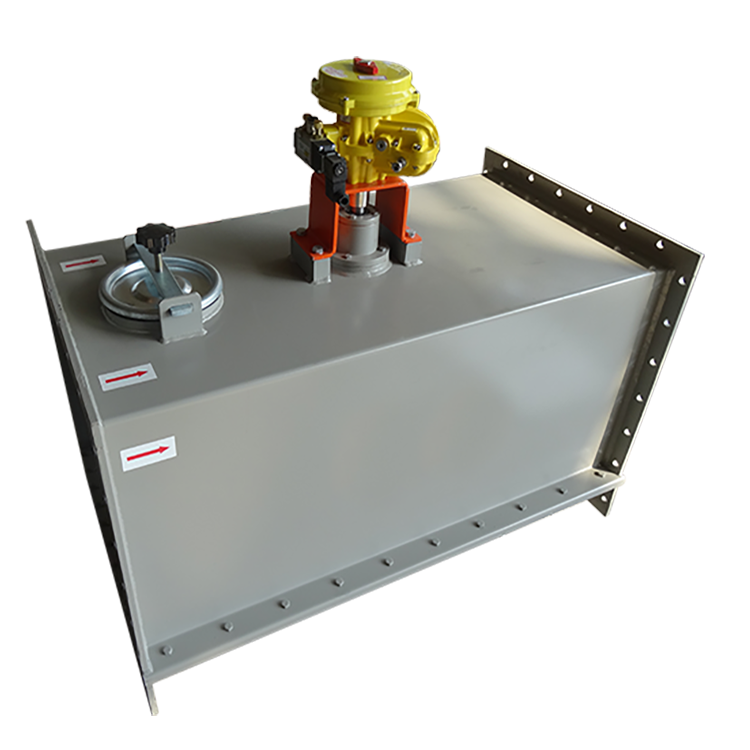

Almost any device that moves any object is called an actuator. Actuators need an energy source. It is divided into three according to the energy they use. Those working with electrical energy are called electric actuators, those working with liquid are called hydraulic actuators, and those working with compressed air and gas pressure are called pneumatic actuators. The pneumatic actuator is used with a valve to move any device or object, just like any other.

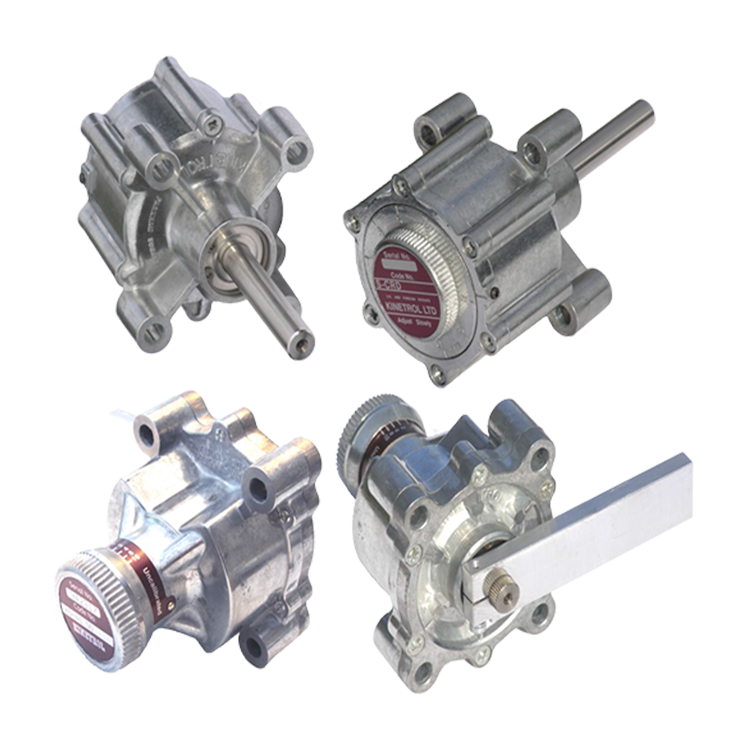

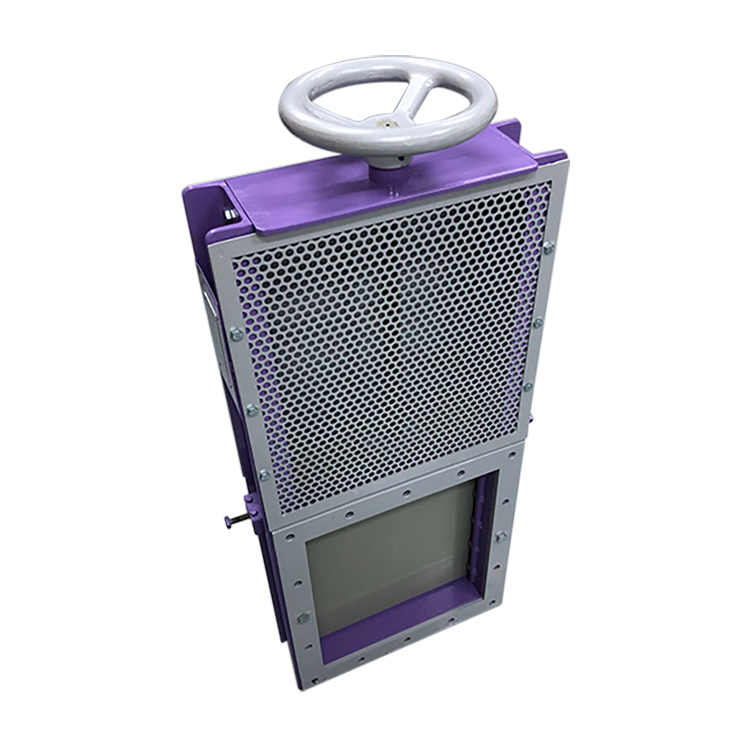

Actuators are also divided into two type according to how they work. Some are designed to move the object forward or backward in a straight line. These are called linear-type actuators. Some also operate in a rotating system with a 90-degree angle, this type of actuator is also called a rotary actuator.

Rotary Actuator Types

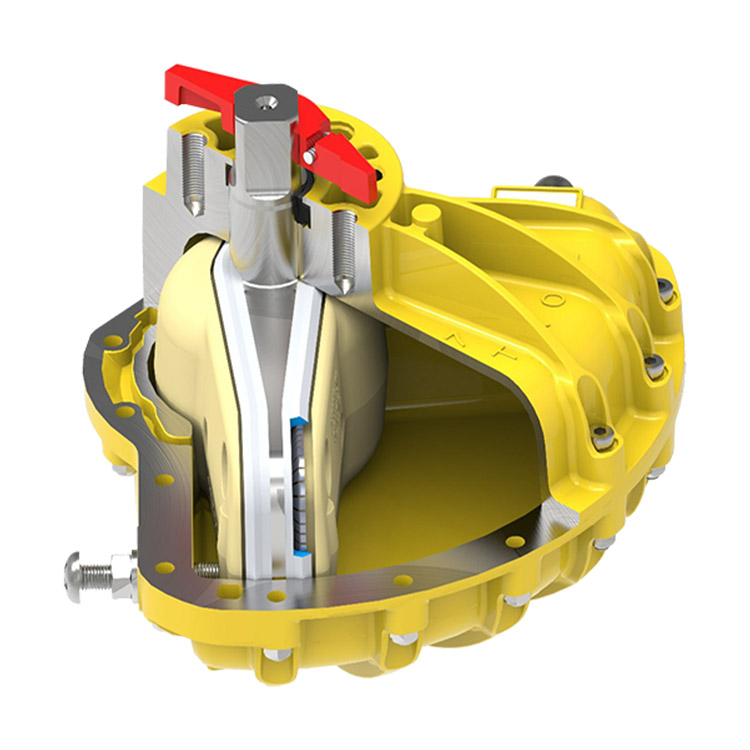

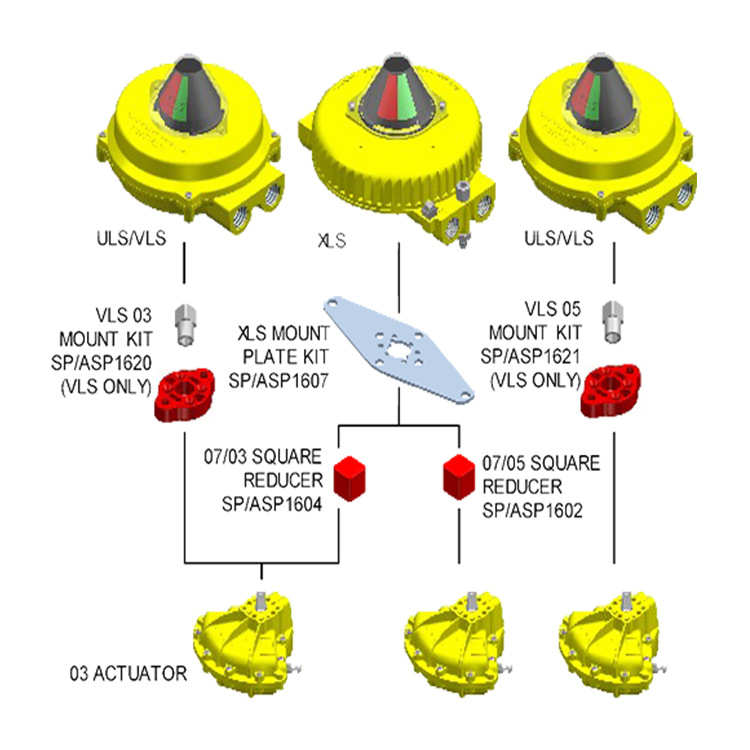

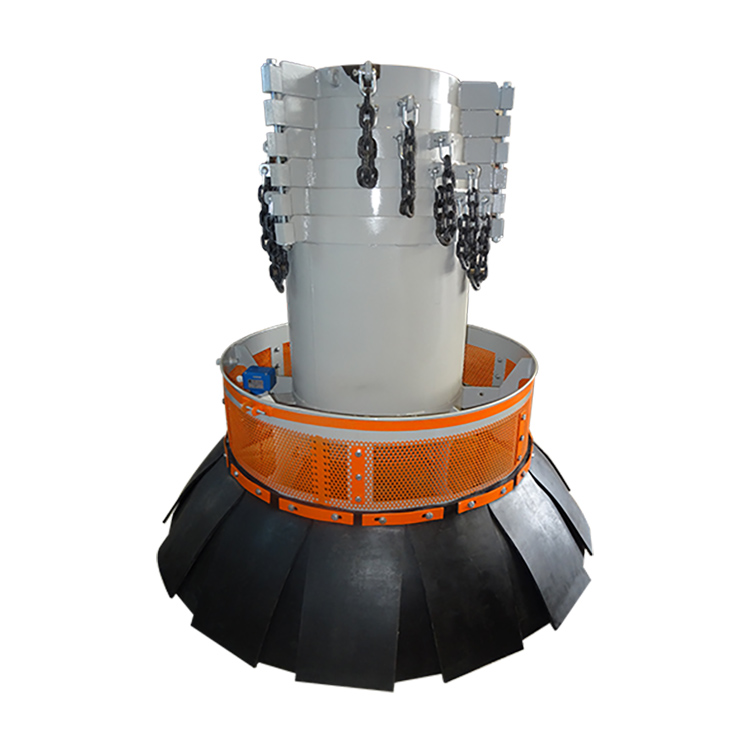

Pneumatic rotary actuators work to create a rotary motion oscillating from compressed air. They are considered among the very durable and reliable actuators. Since they have a very simple and light structure in design, they are very comfortable in both use and assembly.

Like other types of pneumatic actuators, they can be operated in explosive atmospheres. As working principles, it has a mechanism that is divided into two as pinion and rack. Both models are available in single and double-acting versions. But their working mechanisms are different. A pneumatic actuator with a rack pinion has a disadvantage in terms of durability than rotary-type actuators. Damage occurs in the pinion and rack mechanism teeth after continuous movement.

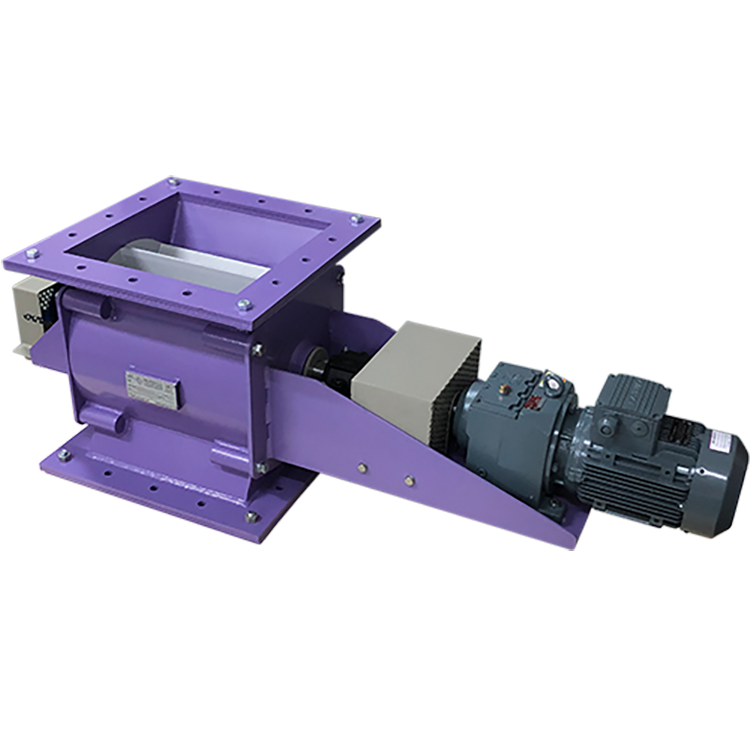

Working Principle of Rack and Pinion Pneumatic Actuators

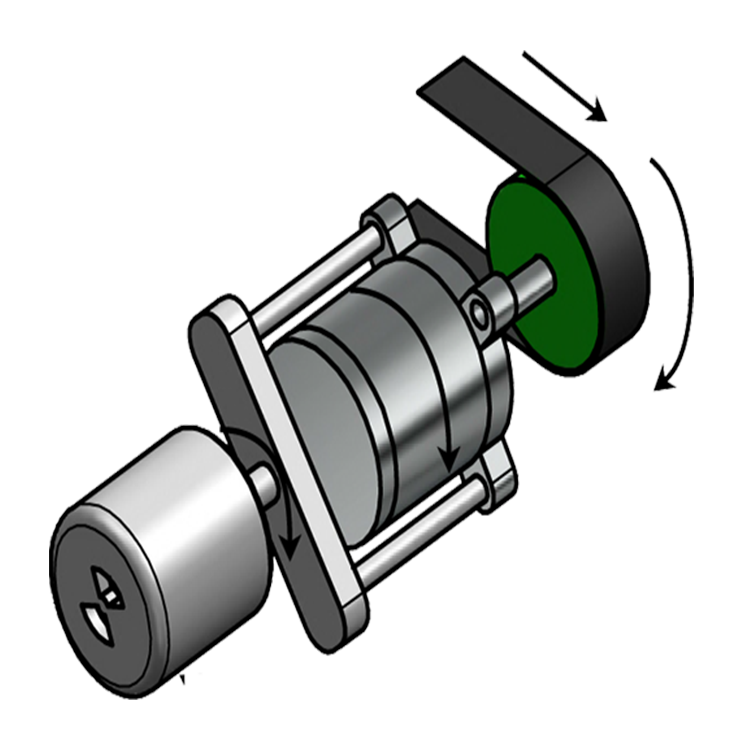

Rack and Pinion Pneumatic of rotary actuators work in conjunction with a cylindrical piston, which is connected to a gear called a rack. From the moment the actuator starts working, the output shaft, piston and rack gear start working together in a linear motion.

There are two racks on either side of a pinion gear. Such pneumatic actuators can work with two racks to double the output torque. Thanks to the drive of the pinion and the rack, the initiated linear motion turns into a female or male output shaft. In this way, the actuator enables the actuation of any flap or valve.

TR

TR