ACTUATOR GENERAL SPECIFICATIONS

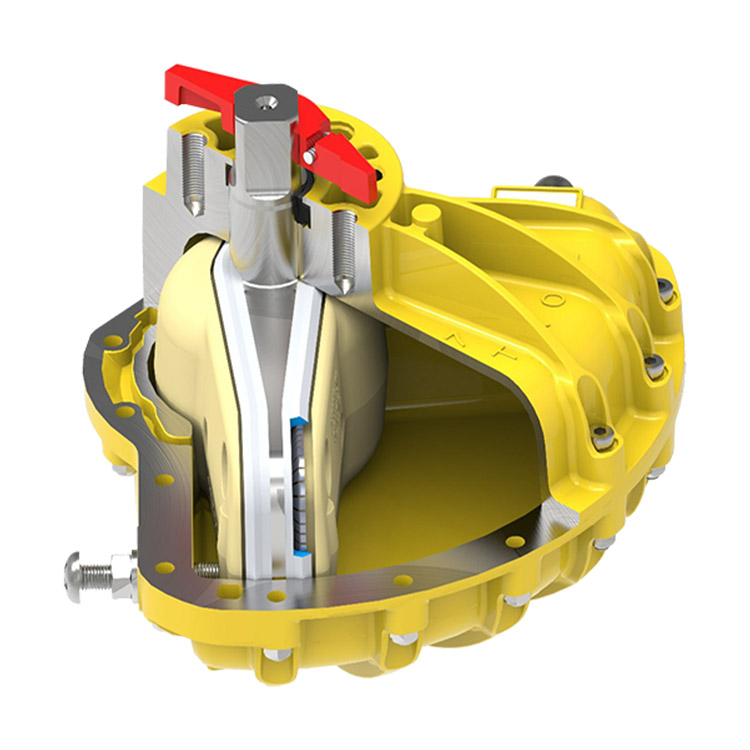

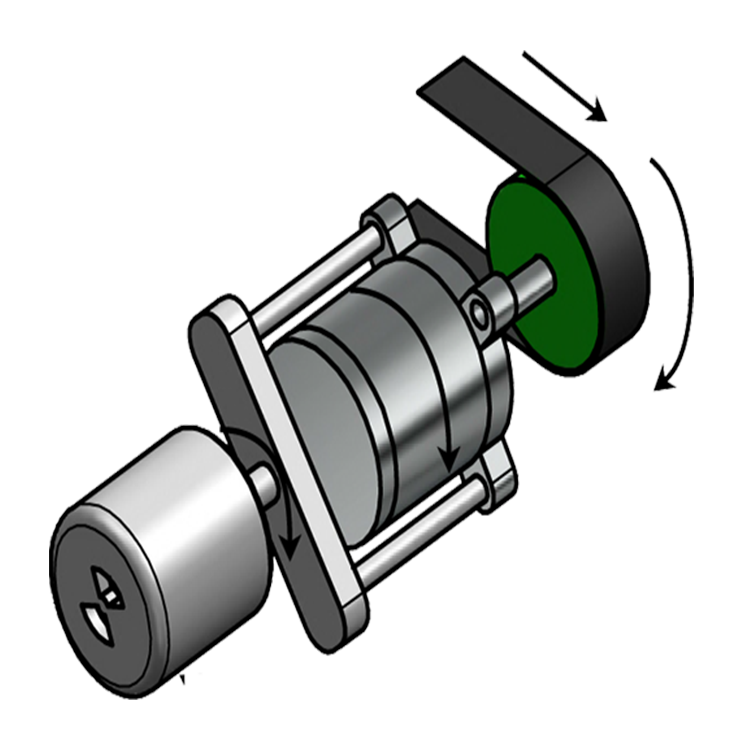

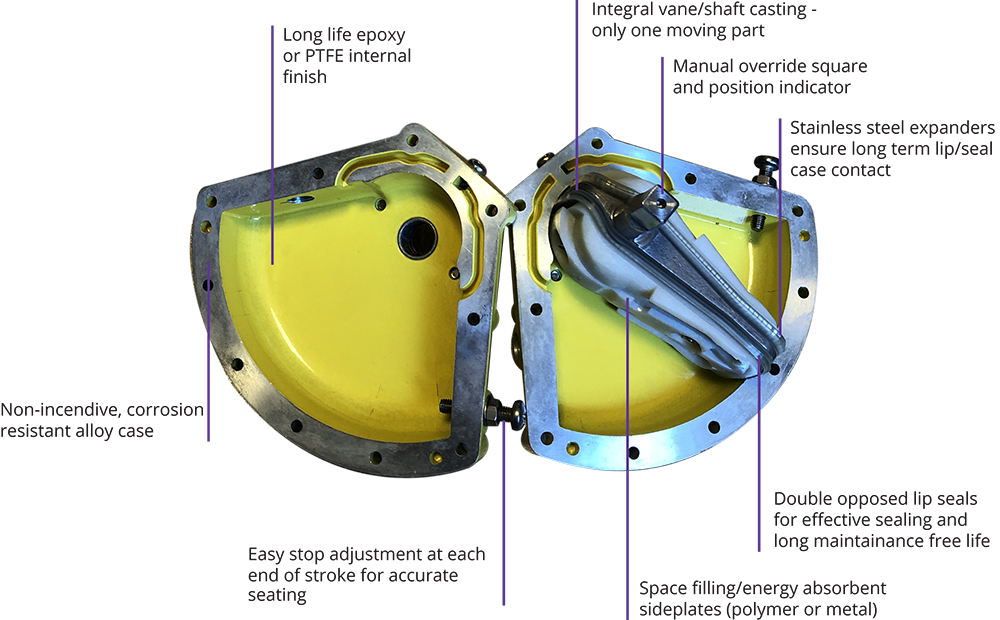

Single moving part: Simplest and most reliable mechanism for quarter-turn rotary actuation.

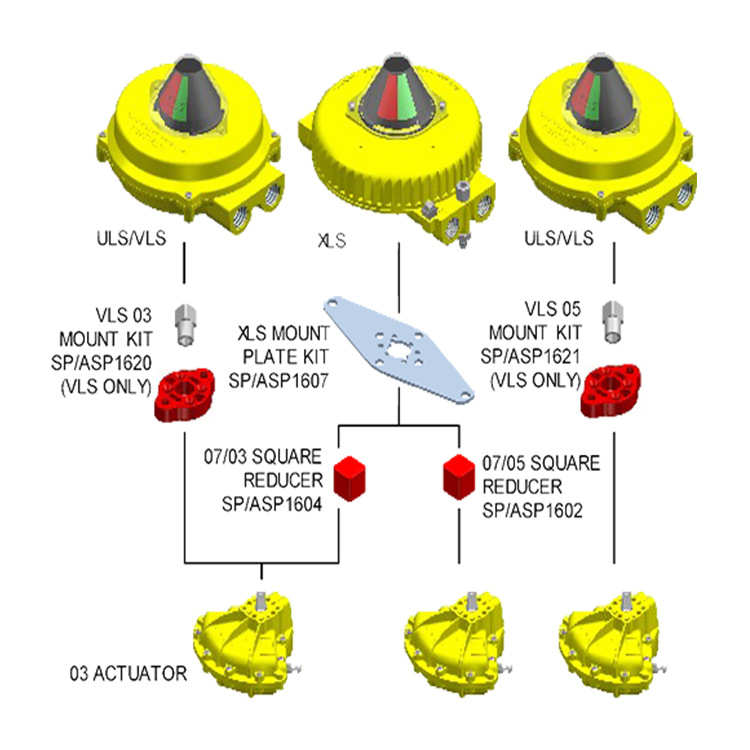

Close couple control modules: Fail-safe spring returns, limit switches, positioners and solenoid valves all close couple to the actuators.

No cranks or gearing: No power loss or backlash – allows accurate positioning.

Durable corrosion resistant finish

Long maintenance-free life: Up to 4 million operations guaranteed.

Compact – space saving – efficient: Best torque/size package available, fast operating speeds, best air consumption, proven design.

Hundreds of thousands of units: in trouble free service all over the world.

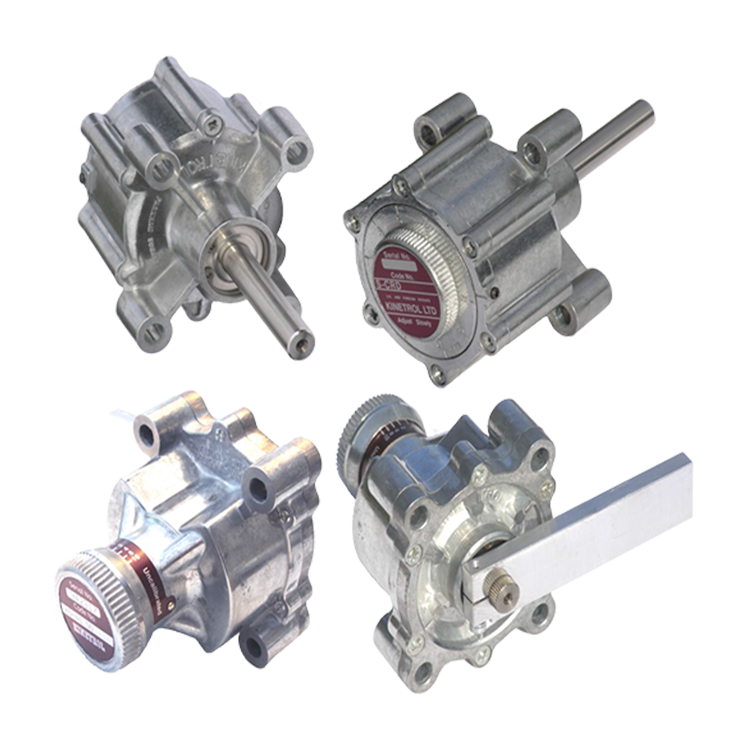

Choice of male or female output drive square – easy to interface to application

Unique serial number for identification and traceability

Materials of Constrution:

Casing:

Models 0M0, 01, 02, 03 & 05 – Pressure die cast ZL16 zinc alloy.

Models 07, 08, 09, 10, 12, 14, 15, 16, 18, 20, 30 & 60 – Die cast or sand cast aluminium alloy.

Vane & Output Shaft:

Models 0M0, 01, 02, 03 and 05 – Stainless steel.

Models 07 to 60 – SG iron, zinc plated.

Shaft bushes: PTFE coated bronze.

Seals:

Moulded polyurethane.

High and low temperature seals also available – contact us

Seal expanders:

Stainless spring steel.

Couplings:

Weldable mild steel, zinc plated.

Working temperature range:

Standard: -40 C to +80 C

High temperature option: -20°C (-4°F) to +100°C (212°F) using temperature seals for higher temperatures with special equipment – contact us

If consulted Kinetrol may, under certain circumstances/conditions, be prepared to extend its high temperature limits

Low temperature option: -54°C (-65°F) to +60°C (140°F) using temperature seals include option “W” at end of actuator coding.

Maximum recommended working pressure: 100 psi (7 bar)

Maximum overload pressure: 150 psi (10 bar)

Certification

AppLICATIONS

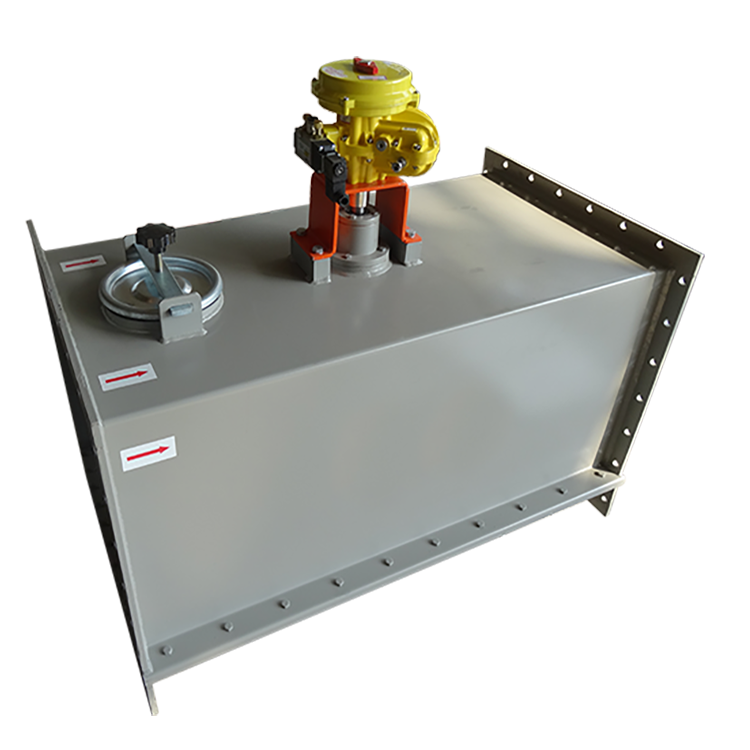

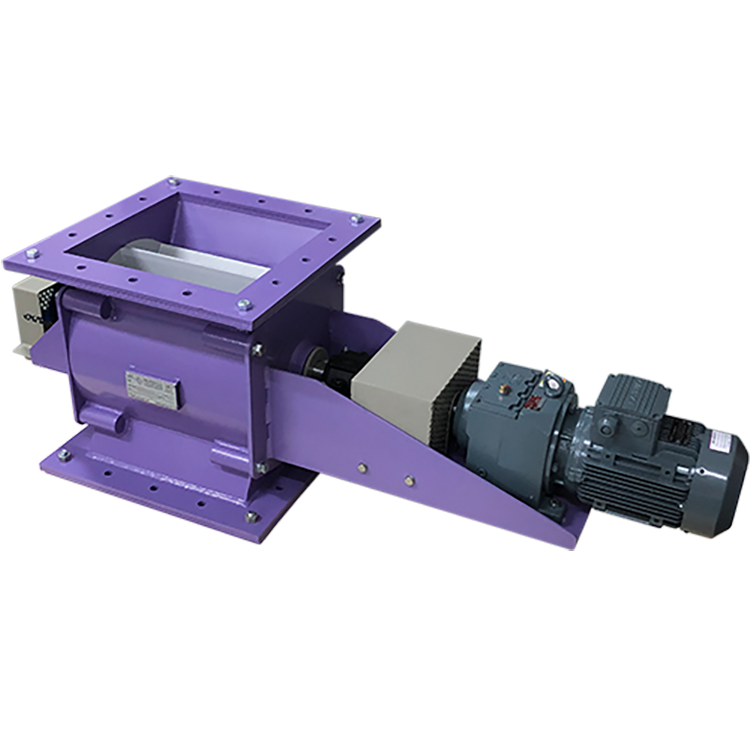

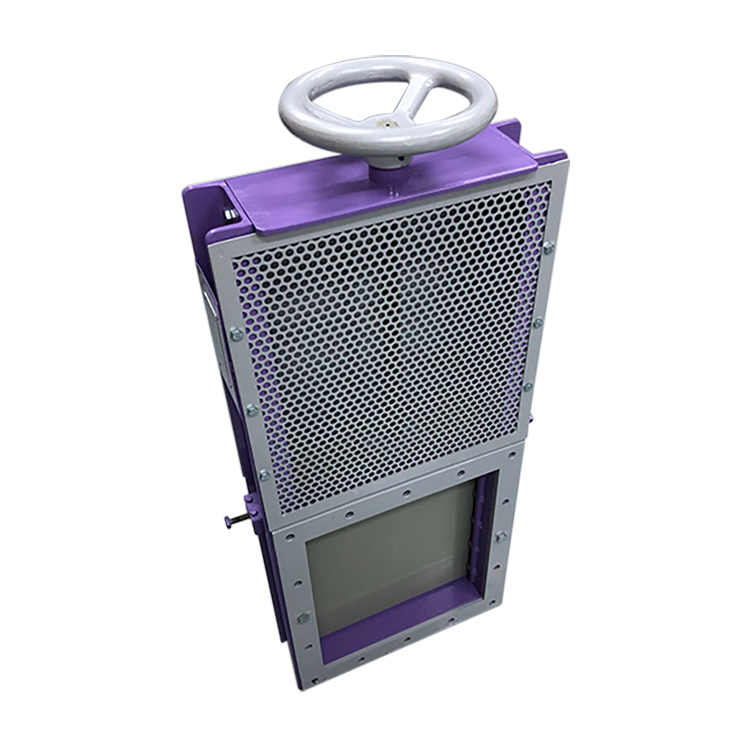

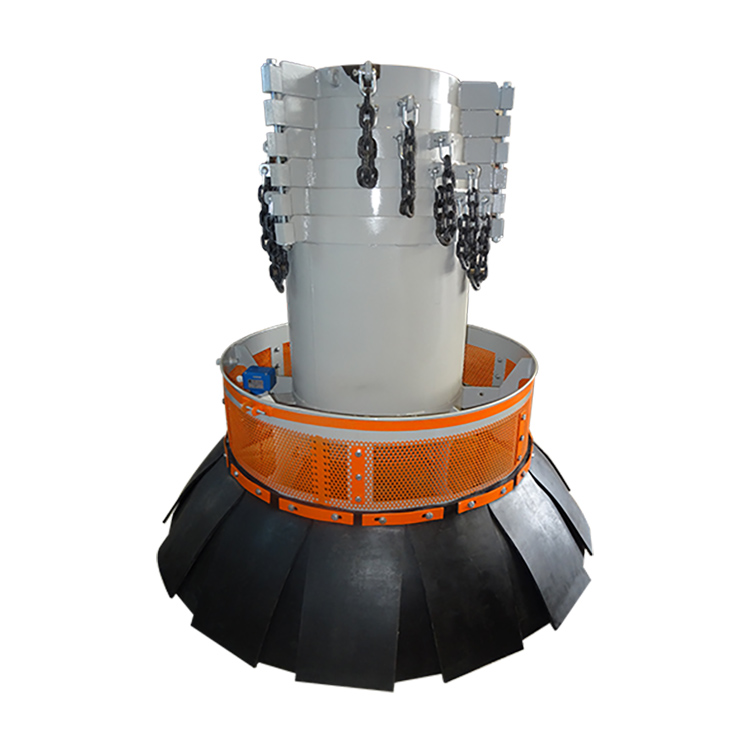

Operation or positioning of ball, butterfly, plug and control valves, ventilation dampers and automatic doors. Uses also include movement and positioning of components during manufacture – in fact anything that needs to be turned through 90° or less, automatically or by remote control.

TR

TR