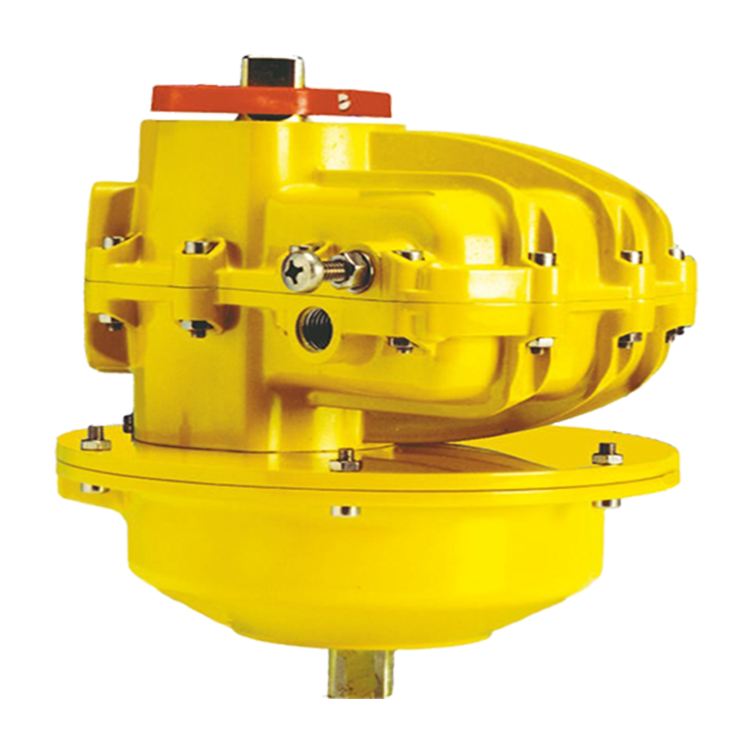

Kinetrol® 180 Degree Actuator

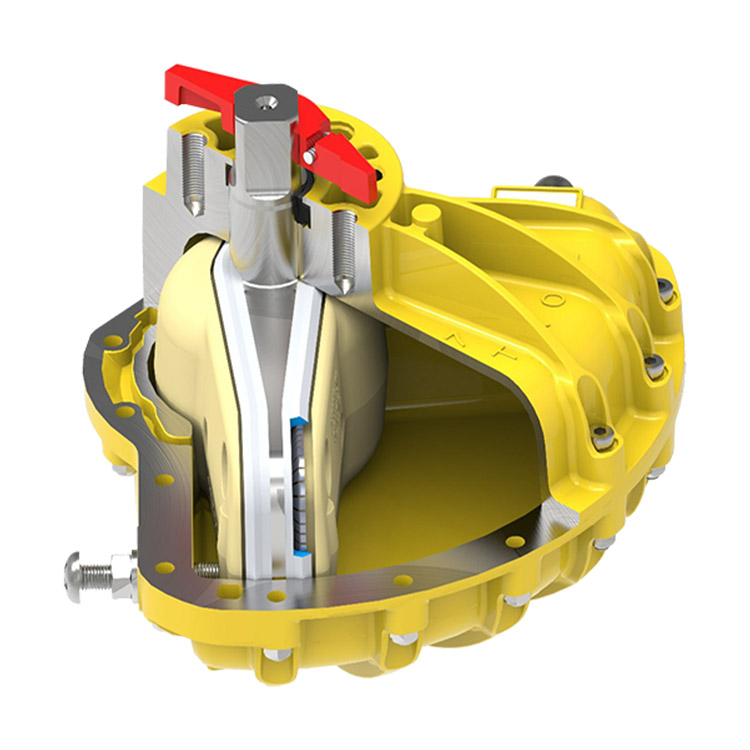

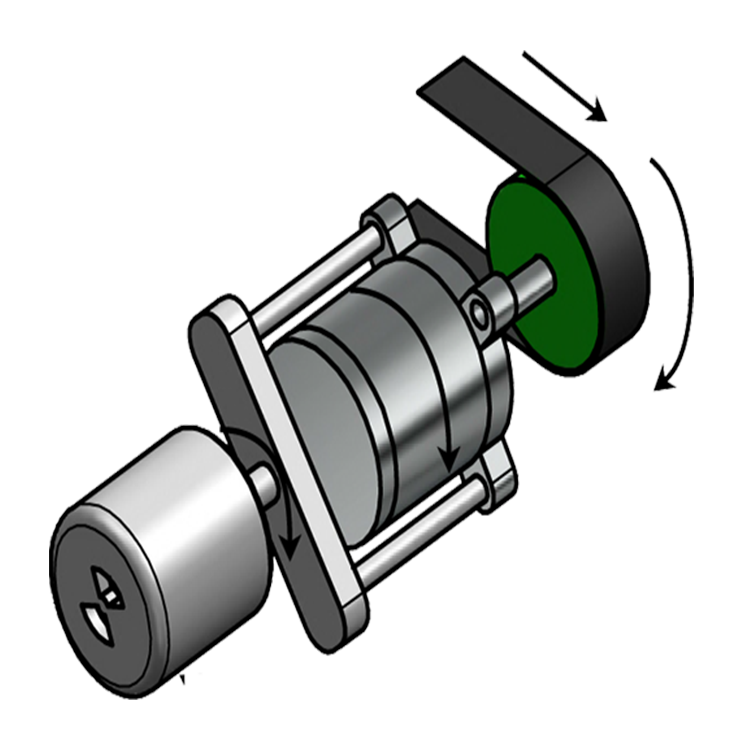

Kinetrol’s 180° actuator is produced by adding a 2:1 step-up linkage onto the output shaft of well proven 90° vane actuators.

Specifications

Simple compact unit: No external moving parts

Unique linkage design: converts to 180° travel 120° option available

Constant gear-up ratio through travel range: Hence constant output torque

Rolling contact linkage mechanism: Ensures low wear, long life, low friction

Linkage sealed for life: Protected from the environment, long maintenance free life

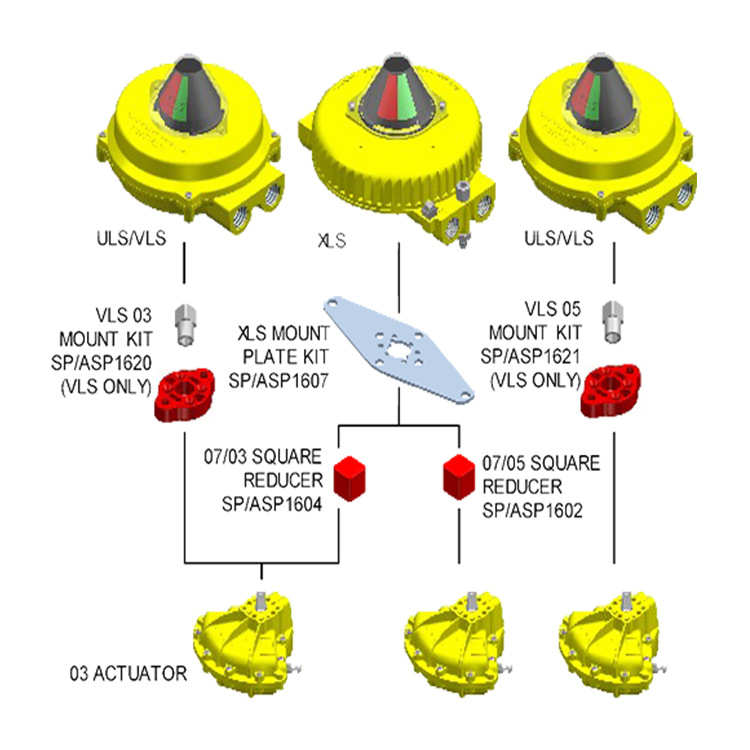

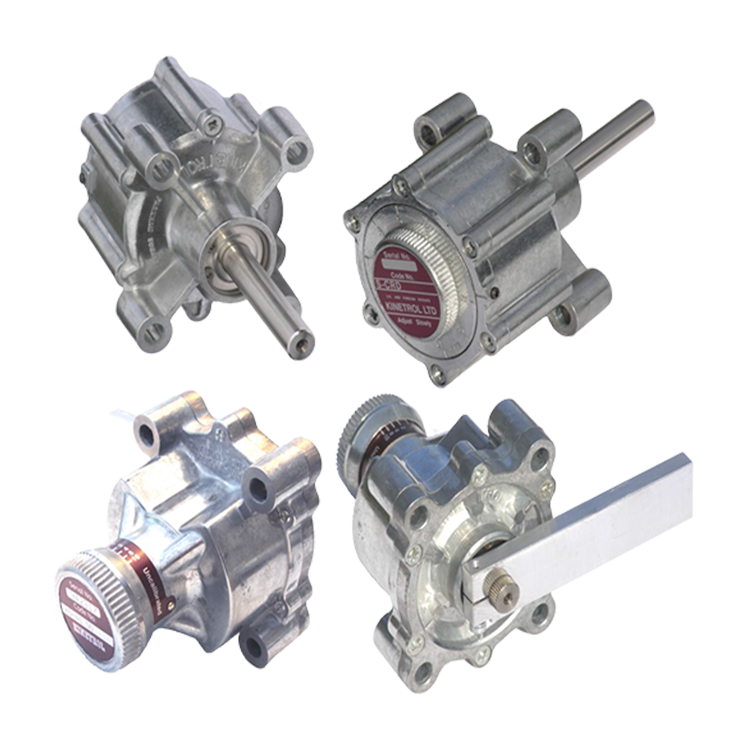

Compatible with all Kinetrol modules: Direct mounted spring returns, limit switch boxes, positioners etc.

Adjustable endstops

Operation

Kinetrol’s 180° actuator is produced by adding a 2:1 step-up linkage onto the output shaft of well proven 90° vane actuators.

Factory fitted, direct mount linkage units are available to suit model 02, 03, 05, 07, 09, 12, 14 and 16 actuators, giving a neat single unit with no mount kits or brackets. The linkage’s unique geometry gives constant 2:1 step-up so that the output torque remains constant throughout the actuator’s travel.

The all-steel mechanism of the linkage employs rolling contacts to minimise frictional losses and wear, and to maximise life. The linkage is lubricated for life, and encased in a robust, fully sealed, die cast alloy casing. Exterior surfaces are protected by a corrosion resistant epoxy stove enamel finish. Standard adjustable endstops on the 90 degree actuator can be used to set the angle of travel. The other end of the 90 degree actuator allows the full range of Kinetrol modular accessories to be fitted directly.

120 degree actuators are also available with adjustable end stops to give up to 133° of travel for the above model range -contact Mor Endüstri Ltd. for details.

Documents

180 Degree Pneumatic Actuator Datasheet

TR

TR