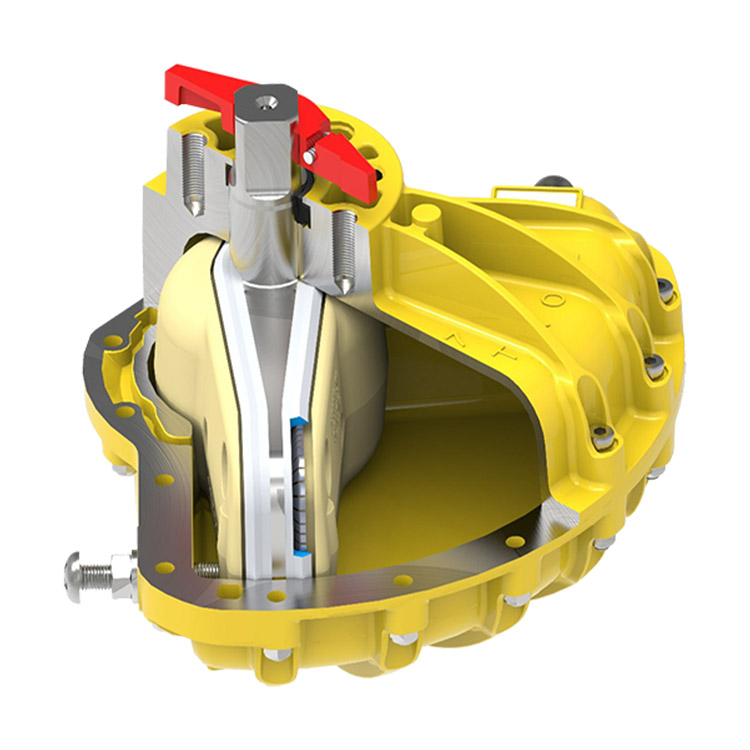

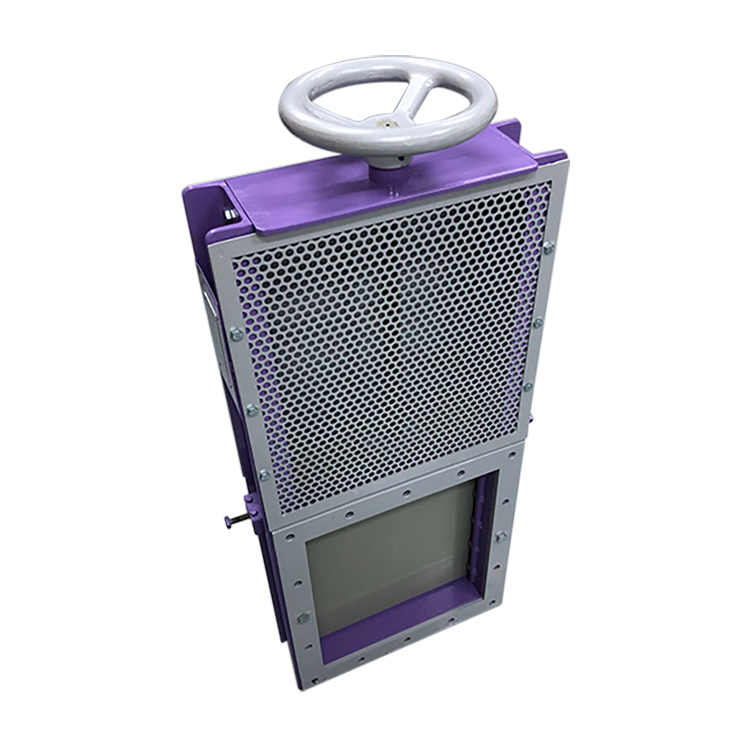

Diverting Gate

Diverting Gates direct the material entering through the upper inlet port to two or three separate outlets. The body of the pant valves can be steel or stainless steel and can be coated specially according to the material passing through.

Our references will be shared upon request because of customer confidentiality.

Please contact us by sending an e-mail to info@morendustri.com. We will be glad to help you.

Description

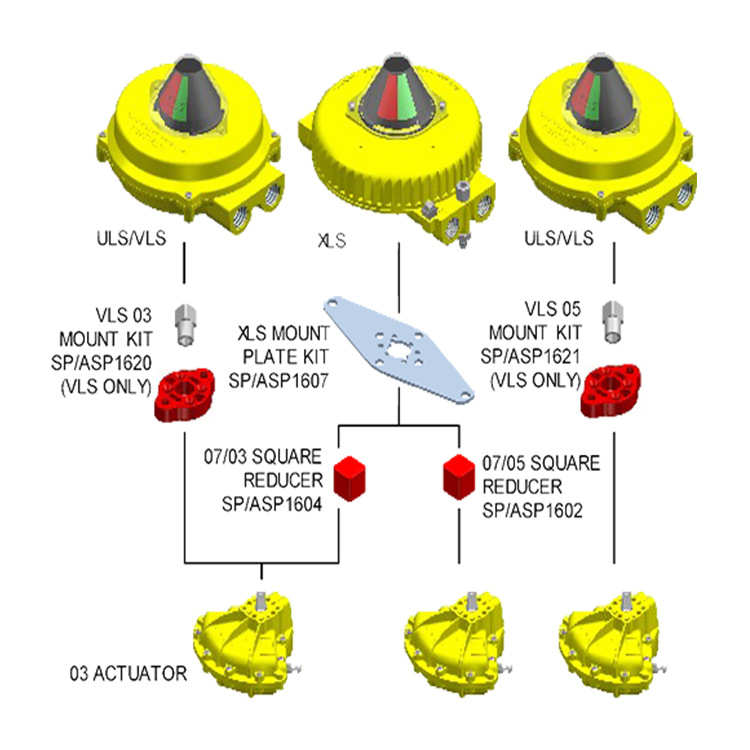

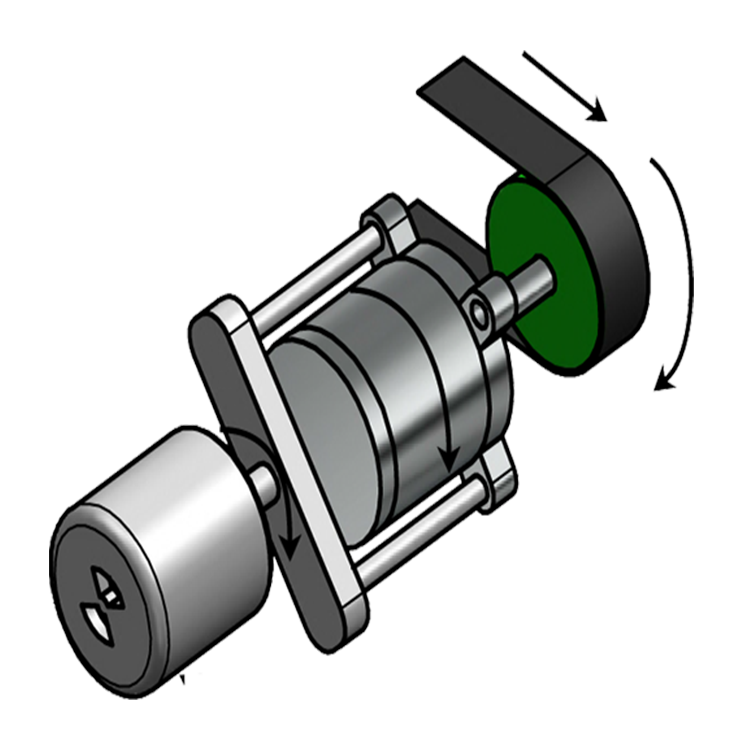

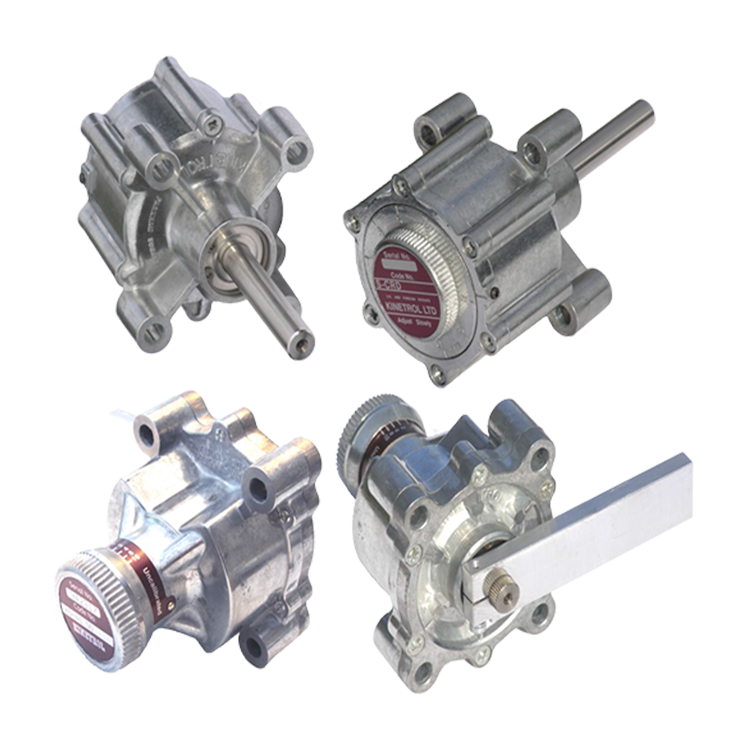

Diverting Gates direct the material entering through the upper inlet port to two or three separate outlets. The body of the pant valves can be steel or stainless steel and can be coated specially according to the material passing through. They are used for cement, lime, raw meal, coal meal and other pulverulent, non-sticky materials in redirecting or dividing flows of materials. Regarding the flow direction, inlet dimensions or shape, the diverting gates are manufactured in different types; regarding to the temperature, size or wearability of the diverted material, the diverter valves are manufactured with different materials. The drive system choices are manual drive, pneumatic drive or motor drive.

Specifications

- Resistant Casing

- Good Sealing Effect

- Simple Access and Minimum Maintenance

- Good Flow Control

Where to use

- Silo and Bin Oulets

- Feeding Rotary Packer

- Feeding Bulk Loading Point

- Feeding Flowmeter

- Feeding Belt Weigher

TR

TR