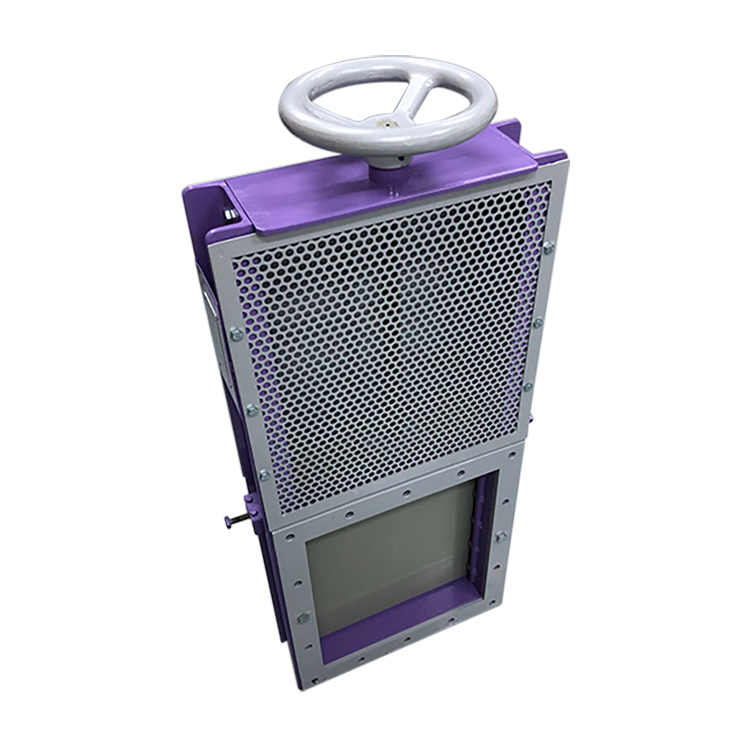

What is Slide Gate?

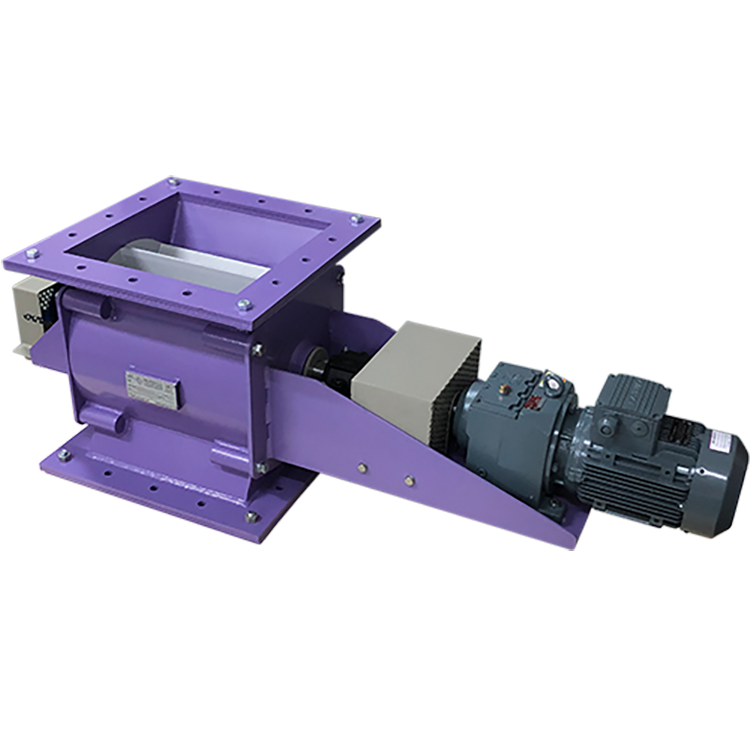

Gate Valve is also known as knife valve or gate valve. Knife valves are used to control the flow of free-flowing materials. Slide valves have a sliding plate on the valve body. Thanks to this plate, the free fluid is completely cut off.

It is connected to auxiliary equipment such as sliding flaps, stock silo, bunker, flow chute, conveyor. The gate valve gives way to the fluid by the movement of the throttle and then activates the gate valve to stop the flow.

What are the Features of the Slide Gate?

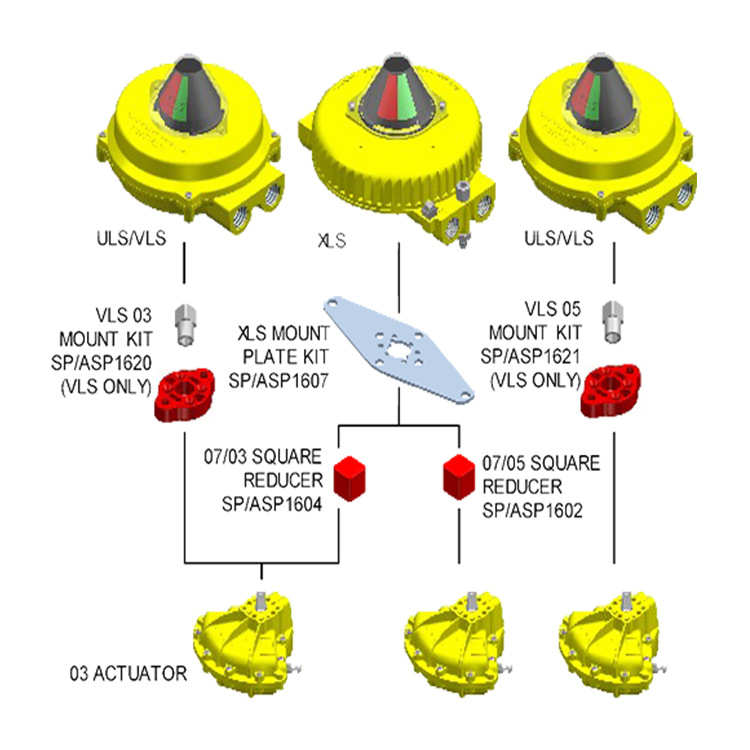

The sliding damper is preferred as fully open or fully closed. Two types are produced: F4 and F5 type gate valves which are available in old type networks. The difference between these gate valves is the installation length. There is no other difference.

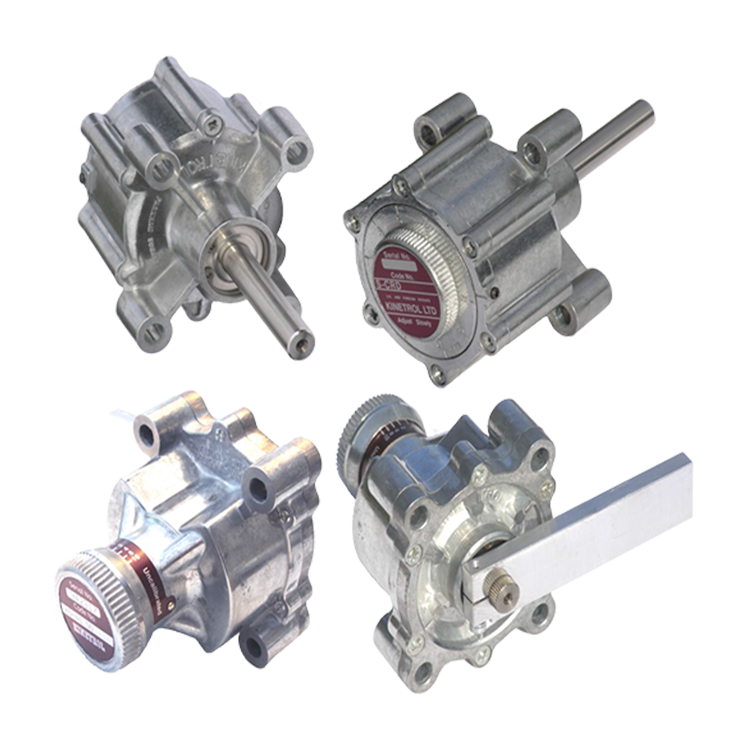

Gate valves are maintenance-free, bidirectional valves. The slide valve is available for underground or above-ground applications. Pressure loss is very low. It works with low torque. It is patented.

What are the Materials of Slide Valves and What are the Purposes of the Materials?

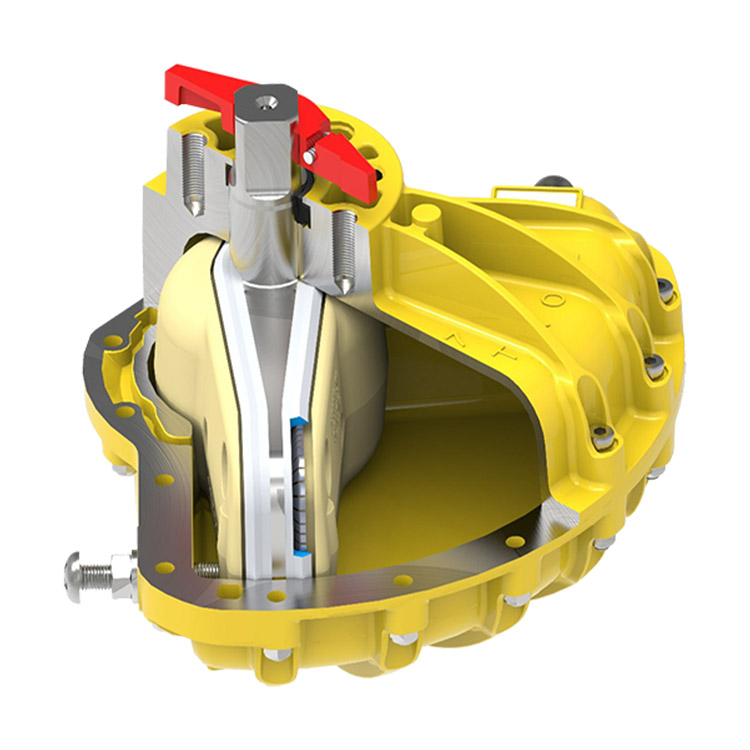

The slide valve is used to cut or start the flow of powder fluids and some fluids in industrial areas. Sliding flaps have silos in use. There is a sliding damper under the silos, at the bunker outlets before the spirals. There is a slider parallel to the ground inside the sliding flap. This slider is used to cut or open the flow. Gaskets are used on the surface of the slide so that the sliding valves do not leak the fluids.

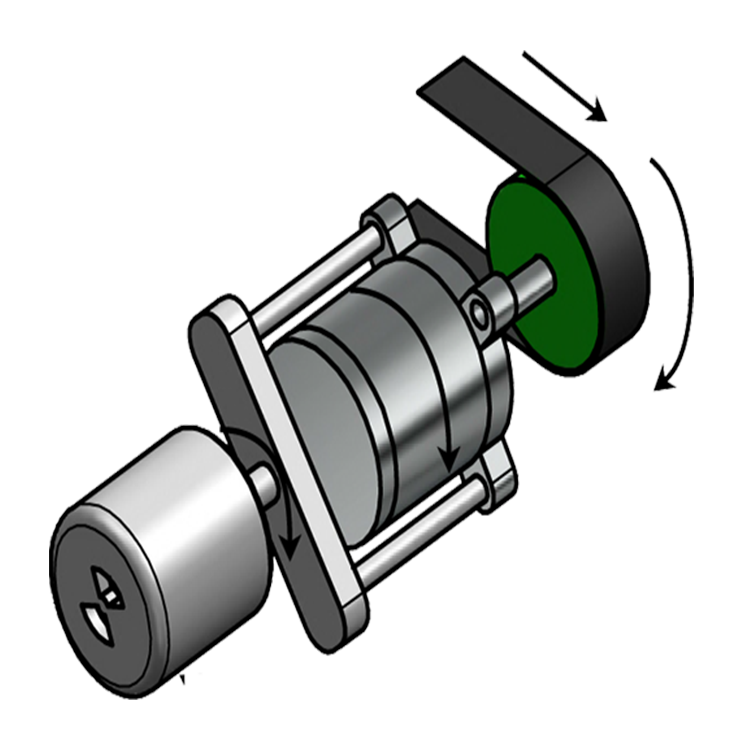

For more effective sealing, SINT material is coated on the surface of the slide part of the slide valve. In this way, a more sensitive product is obtained and the impermeability is maximized. Sliding flaps have a discharge area. This discharge area is square or circular. If the sliding flaps are to be used in the food industry, they are produced from AISI stainless steel. Sliding flaps have an opening and closing operation. This process can be done with a piston or a manual handle.

What are the Advantages of Sliding Gate?

The sliding valve is least affected by the weight of the load compared to butterfly valves. There is no need for a separate area for opening the sliding flaps. It can be used with all kinds of materials. It is produced with carbon steel, stainless steel, sealing elements, Epdm, polyurethane materials, so it is durable and long-lasting.

Mounting is easy. It has a structure resistant to abrasion. Gate valves are the valves with the highest tightness. Gate valves have certificates.

What are the Disadvantages of Sliding Valves?

Gate valve is not opened or closed in a series. For this reason, gate valves cannot be used in jobs that require continuous opening and closing. The assembly and maintenance of the gate valves are somewhat cumbersome. A large area is needed for maintenance and assembly.

Gate valves are not used with high pressure. When used, leakage may occur from the valves due to the high load on the pipe. If the gate valves are used as fully closed, the gate may create high pressure, even if it is small. In this case, it can damage the operation of the system.

How is the Pressure Resistance of Slide Gate?

The gate valve or gate valve is not designed for high pressure. They cannot hold high pressure. For this reason, the gate valve is not used as a breaker in pneumatic conveying lines. It is produced for powder fluids.

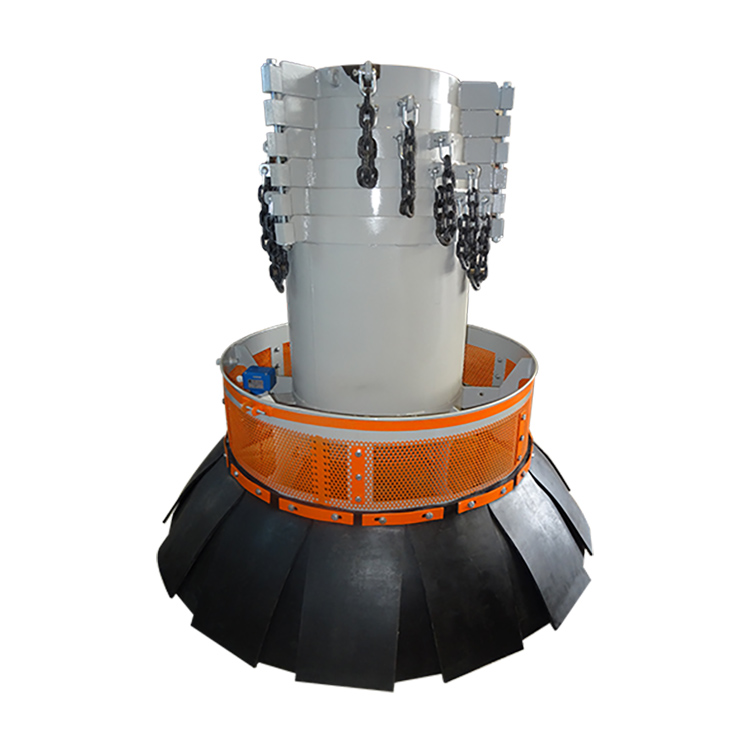

Where and For Which Products Is The Sliding Gate Used?

Sliding flaps are used in many raw material passages. There are also valves in many materials in the industrial area. The materials used with the sliding flaps are cement, flour, gypsum, lime, bran, calcite, granules PVC, wheatgrass, barley, corn, corn flour, sunflower seeds, coal dust, sand, bentonite, salt, granulated sugar, cocoa, starch, in the form of ash and sawdust. Gate valves are used in textile, power generation, petrochemical, shipbuilding, food facilities, chemical industry, paper mills, and refineries.

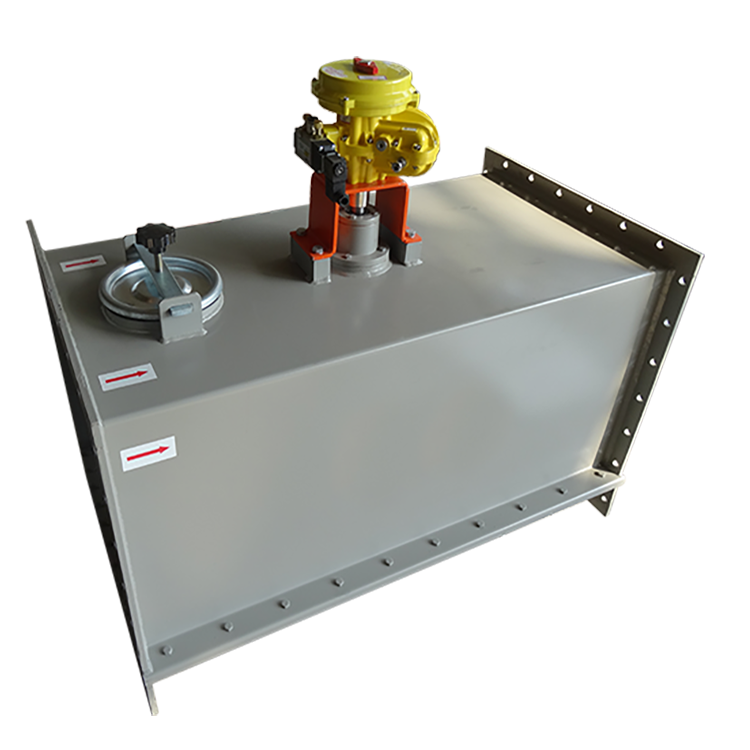

Silo Sliding Bottom Flap What is it?

It is produced as a sliding valve, pneumatic piston, electric motor, or manual type. There are different connection options according to the silo discharge opening. Under-silo sliding flap is used for bunker and silo discharge. Silo sliding bottom flap is a system designed for conveying dry bulk materials. The mouth part of the slide valve serves to provide full flow. There are no materials or discs in the silo sliding bottom valves to prevent the flow so that the fluid can pass easily. Silo sliding bottom flaps eliminate dust leakage and problems such as clapper jamming.

TR

TR