What is Solenoid Valve? Solenoid Valve Types and Usage Areas

A solenoid valve can be briefly defined as a valve that opens and closes with an electrical signal. A solenoid valve is a valve used for fluids such as air, gas, oil, water, and water vapor. A solenoid valve is produced to control these fluids, and this is its main purpose.

The materials inside the solenoid valve are as follows: Inside, there is a fixed core, a hidden coil, the ends of the coil, solenoid coil, moving core, spring, and disc materials. While the solenoid valve is changing position, a DC or AC voltage up to 220 volts is sent to the coil for electrical energy. Compressed air is filled when the contents of the coil are drawn. The reason for this situation is magnetization.

How Does a Solenoid Valve Work?

Before moving on to the working principle of the solenoid valve, it is useful to learn the names of the internal structure. The internal structure of the solenoid valve is valve body, outlet line, inlet line, Solenoid / Coil, cable entry, pressure bar, spring, and orifice. After all this, we can move on to how the Solenoid valve works. The solenoid valve can work with an alternating current or a direct current. Solenoid valves must be supplied with the correct voltage for their operation. Not all solenoid valves work with the same voltage.

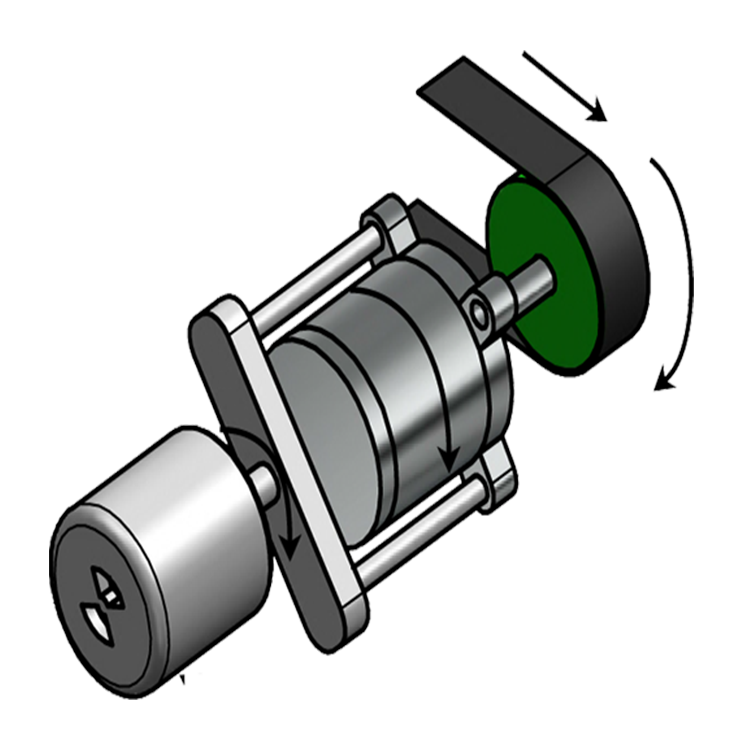

While the solenoid coil is cylindrical, it is turned into a magnet by applying an electric current. The coil connected to the diaphragm in the valve system is applied downward pressure to the iron core and a spring inside. If the coil is connected to the network after pressing it down, the iron core and the diaphragm with a mechanical bond is pulled upwards and when the valve is opened, different fluids such as air, oil, water, or water vapor are allowed to pass through the inlet on the left. On the other hand, the process is completed from the exit line.

What Does a Solenoid Valve Do?

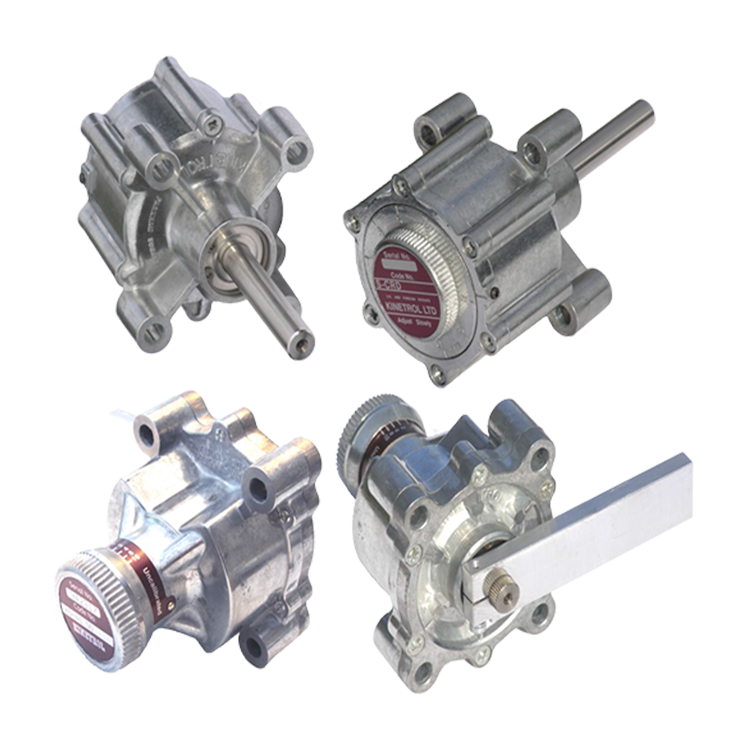

A solenoid valve is an effective system used in the control of fluids with various properties, namely oil, air, water, and steam. Control is provided by this system. If you want to choose a solenoid valve, you can choose from solenoid valves according to the pressure and temperature of the fluid. In this way, you get a more useful solenoid valve. Each solenoid valve has different features. It may vary at some points. For example, solenoid valves may vary in operating voltage and line connection size.

The use of fluids free of particles is also important for a trouble-free process. The pressure of the fluid at the valve inlet must be suitable for the valve. Operations are made by the valve, and filters can be used in this way. Solenoid valves are used in various technological devices, vehicle engines, and different industries. The advantage of using solenoids in technical devices is that the fluids are controlled and the inputs and outputs are made correctly. In the use of electromechanical valves, which are required to keep all these transitions under control, the temperature must be below 150 degrees.

What Are The Features Of Solenoid Valve?

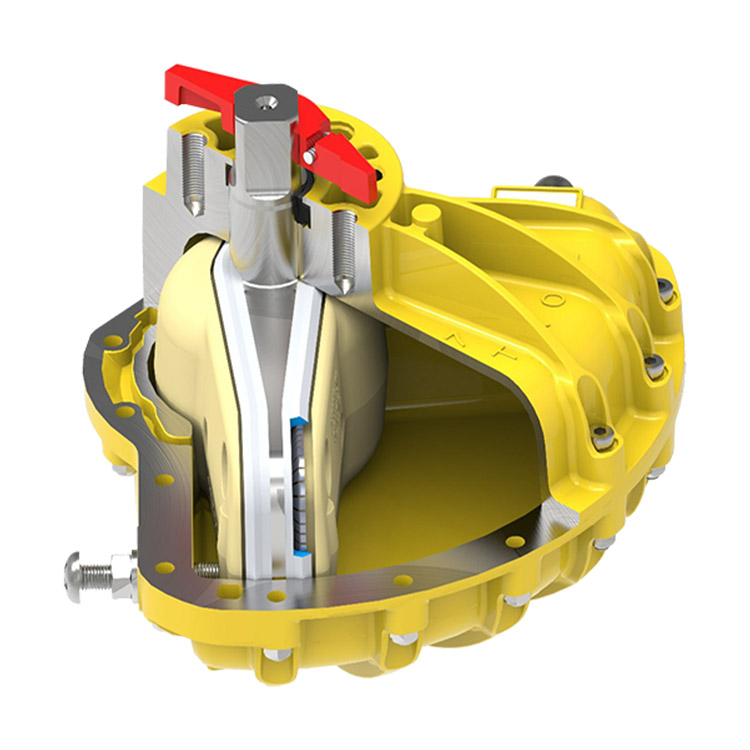

The solenoid valve consists of nine parts. The main body of the valve is located at the bottom. The outlet line, blade, yellow coil, cable entry, piston, spring, and orifice are auxiliary parts after the main body. Two-way or three-way solenoid valves are available.

There is an inlet and outlet section in two-way variety. The other has two exit lines. Only one of them is open in the normal order, but if the solenoid coil is energized, the closed one can become open, the open one closes.

What Are The Types Of Solenoid Valves?

There are types of solenoid valves that can be divided according to the application area, structure, and shape. These varieties are four. The direct-acting solenoid valve is in the form of a Pilot solenoid valve, a Three-Way Solenoid Valve, Four Way Solenoid Valve.

1-Direct Acting Solenoid Valve: This type of valve has low capacity valves. The simplest operating principle belongs to this valve. If the coil is energized, the valve opens and fluid enters through this valve. When the coil is closed, the valve closes and the fluid cannot pass inside. Direct-acting solenoid valve is of two types: Normally open and normally closed solenoid valve.

2-Pilot Solenoid Valve: This type of valve includes a pilot with orifice and main valve, restriction hole, valve diaphragm. The force opens the pilot hole, after which a high-pressure difference occurs. The fluid pressure tries to move the shut-off part upwards, pushing it and thereby opening the valve. In this way, the transition is provided.

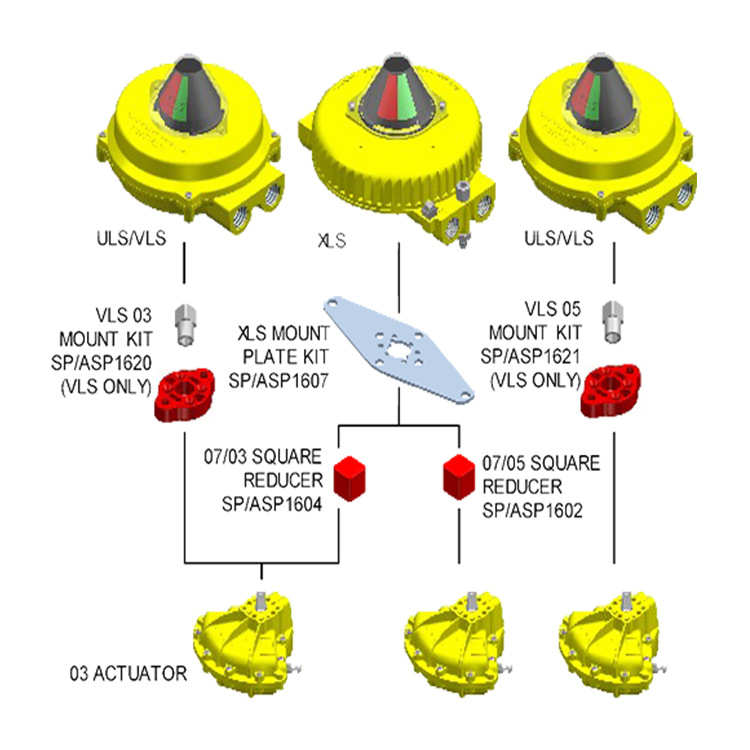

3-Three-Way Solenoid Valve: Three-way solenoid valve is used to operate single-acting actuators.

4-Four Way Solenoid Valve: This type, known as the reversing valve, is preferred only in heat pumps, to select the cooling or heating cycle depending on the need. These valves have three outlet lines and one common inlet line.

TR

TR