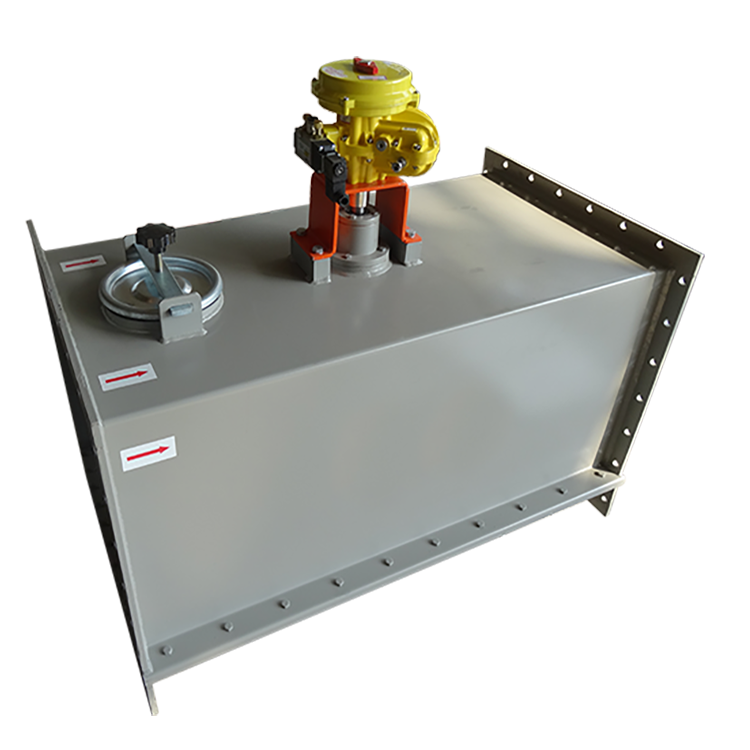

Pneumatic actuators are important for plants. It is preferred among actuators for reliable and high-speed operation. There may also be explosive substances in the environment in where they are used. Pneumatic actuators are one of the most simple and comfortable actuator systems for opening and closing systems.

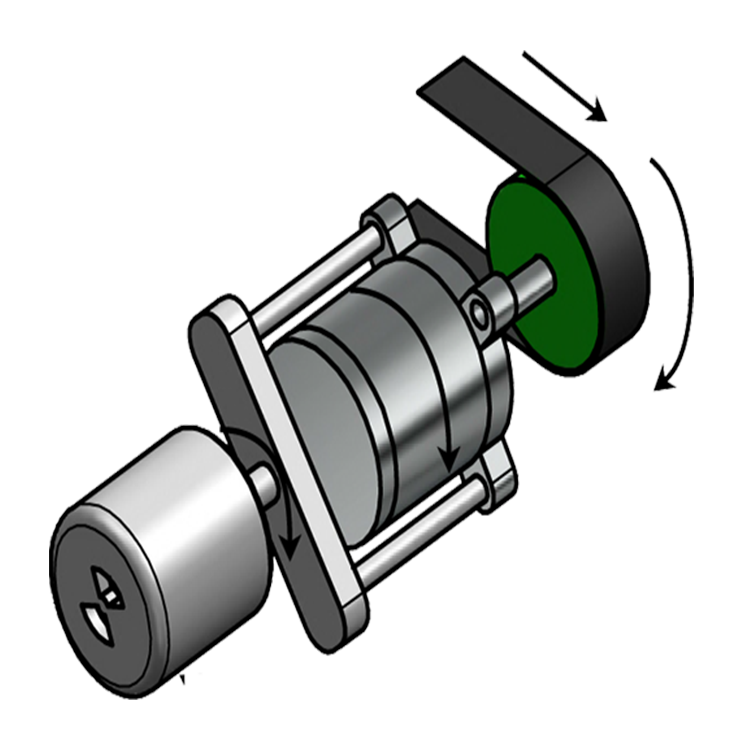

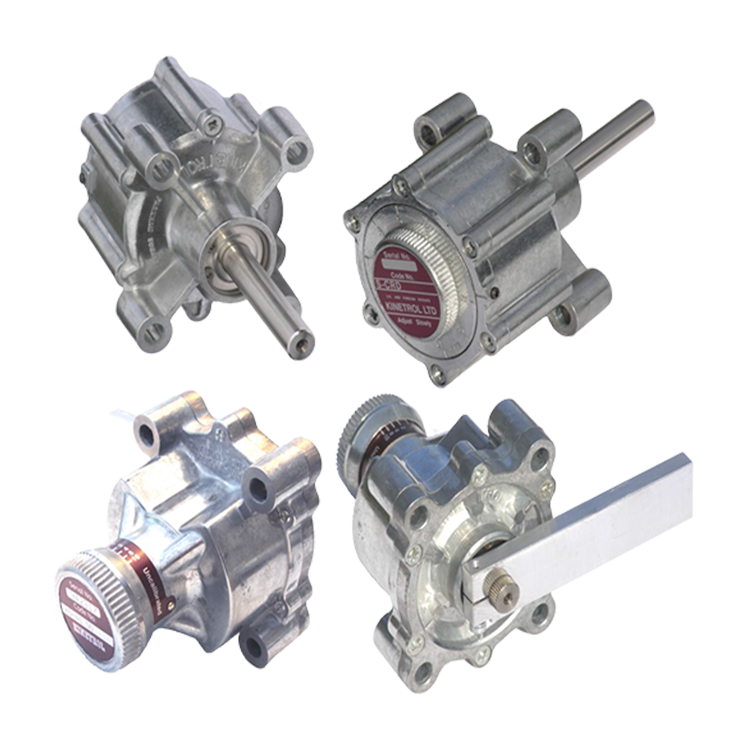

Unlike other actuators, they work by directing air pressure or different gases’ pressure. Double-acting ones work with air applied with pressure at different inlets. Single-acting ones work with the spring system inside. Besides, there are different types, such as rotary type and cylindrical form. All these features should be considered in the selection of actuators. Another point to be considered is the valve type.

What is Butterfly Valve?

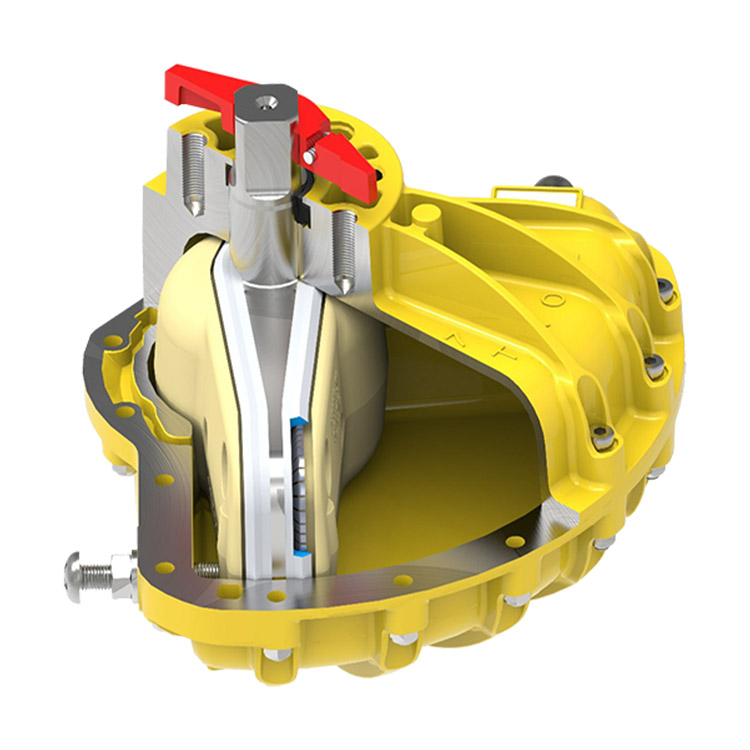

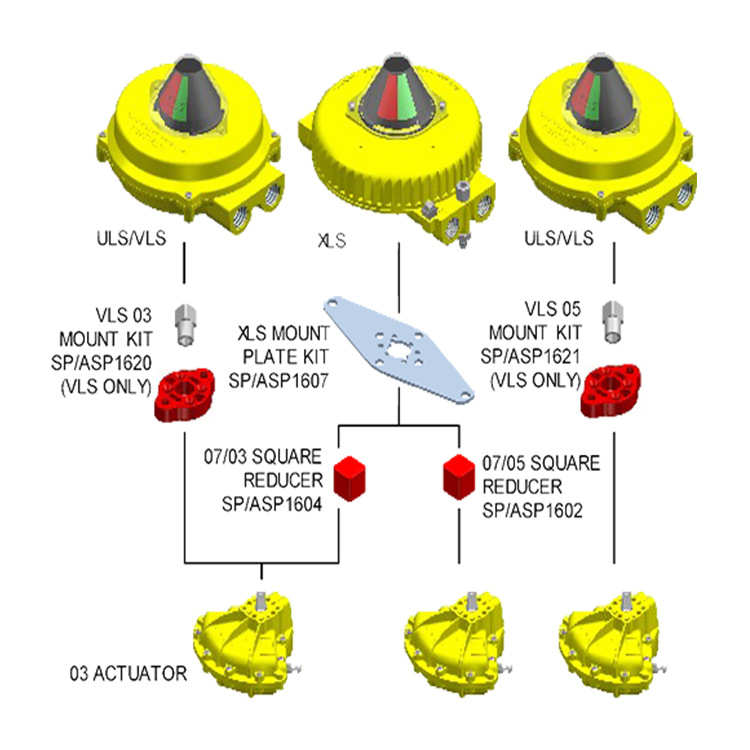

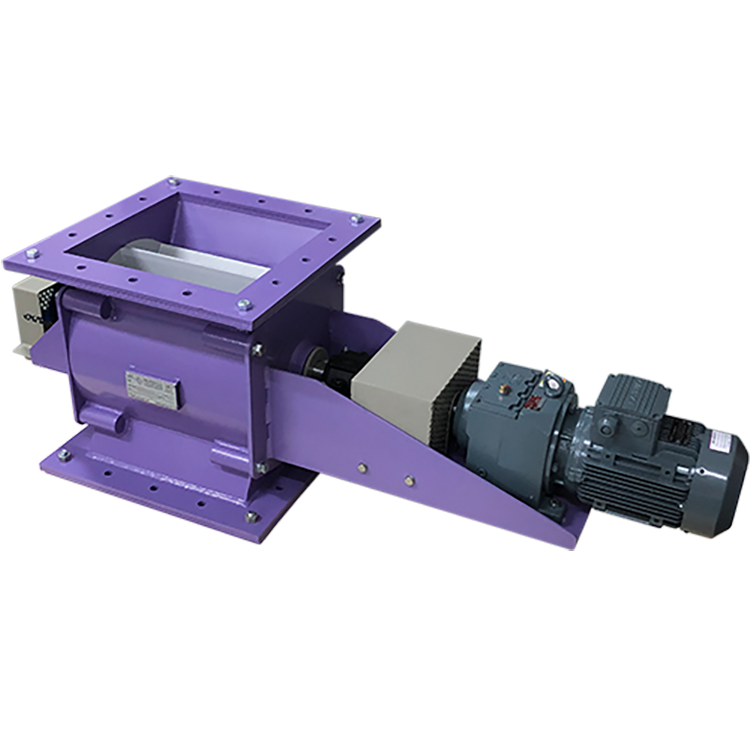

Valves are linked to the direction of compressed air in pneumatic actuators and the operation of the system. Therefore, attention is paid to the selection of valves. Butterfly valves are among the safest valves because they are completely sealed. Such valves occupy very little space in the pipeline and have very advantageous in terms of space. Pneumatic actuated butterfly valve consists of two separate parts as pneumatic actuator and butterfly valve.

It is very easy to apply to the automation system. Pneumatic actuators working with these valves have the feature of working with a very low-pressure loss. Therefore, one of the actuators with the most economical operating system is butterfly valve systems with pneumatic actuators.

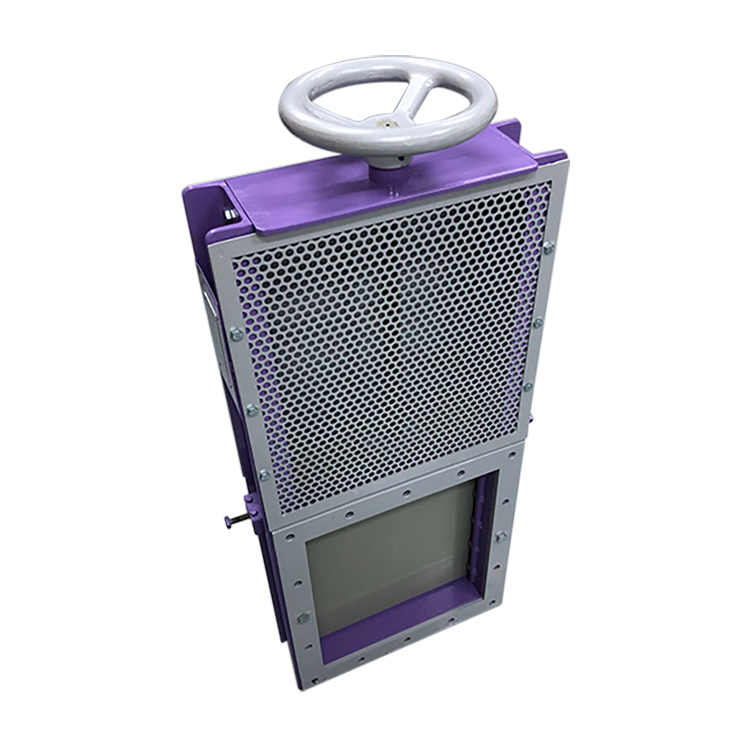

Why Is Pneumatic Actuator and Valve Important?

The opening and closing of actuators used in automation systems or in various industrial industries are important for the safety of the system. Pneumatic actuated butterfly valve works with compressed air. Thanks to a pneumatic actuator placed on the butterfly valve, the operation of the system can be much safer, faster, and more economical. Among the actuators with different types of power drive, one of the most advantageous of pneumatic actuators, as they can be operated with air and can be operated in any environment.

They are also preferred in terms of security, as their starting and closing principles are very simple. They are at a disadvantage compared to the others only in terms of noise, being a bit louder than electric actuators and costing a little more than electric and hydraulic ones when commissioning. However, low and secure modes of operation are important enough to compensate for this disadvantage. Pneumatic actuated butterfly valves are preferred fort he reason of all these advantages.

TR

TR