Actuators are systems used in many industrial facilities. They are also required for automation applications. According to the working principle, actuators can be divided into electric, hydraulic or pneumatic. Unlike others, pneumatic actuators work with a compressor. They may be slightly more expensive than other systems due to the need for a compressor to be installed. They are much more economical systems while operating and in general terms.

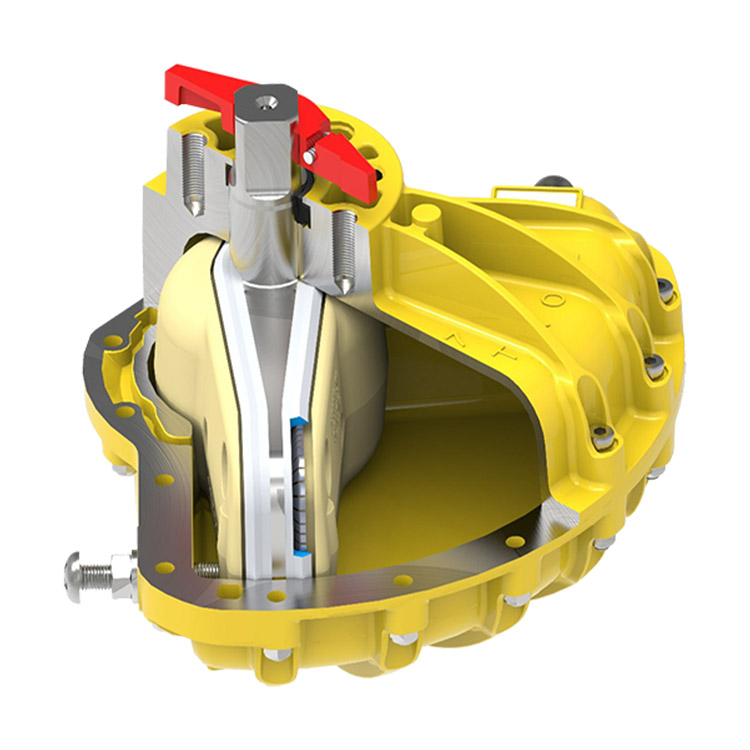

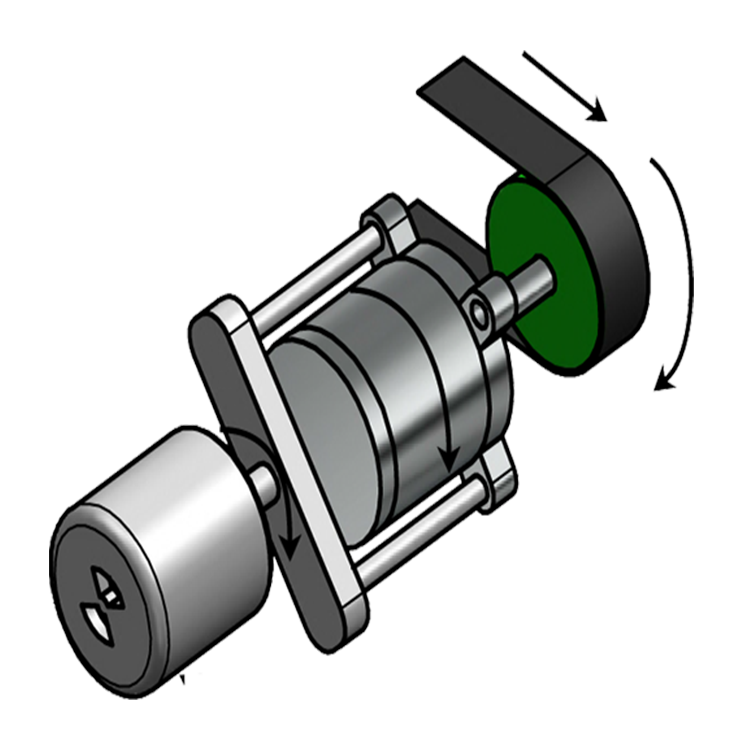

They basically work with the direction of the pressure applied to the compressed air. Thanks to the air discharge, valves inside, they have the advantage of operating at a high speed and less cost. They can be divided into several groups according to the shape of the cylinder, valves. Another way of separating pneumatic actuators is that they are single or double-acting.

How Does a Single Acting Pneumatic Actuator Work?

Single-acting pneumatic actuators can be operated at high efficiency and low cost. The main difference from double-acting actuators is the spring system inside. Thanks to the spring system, single-acting actuators start working without any difficulty. When the spring system is activated, a working actuator stops.

A stationary actuator starts to work with the movement of the spring in it. In this way, the opening or closing of such actuators is made in a much more practical way. As a matter of fact, one of the most important advantage of pneumatic actuators is that they can work as closing systems and to close immediately in case of an emergency.

High-Security Working Principle

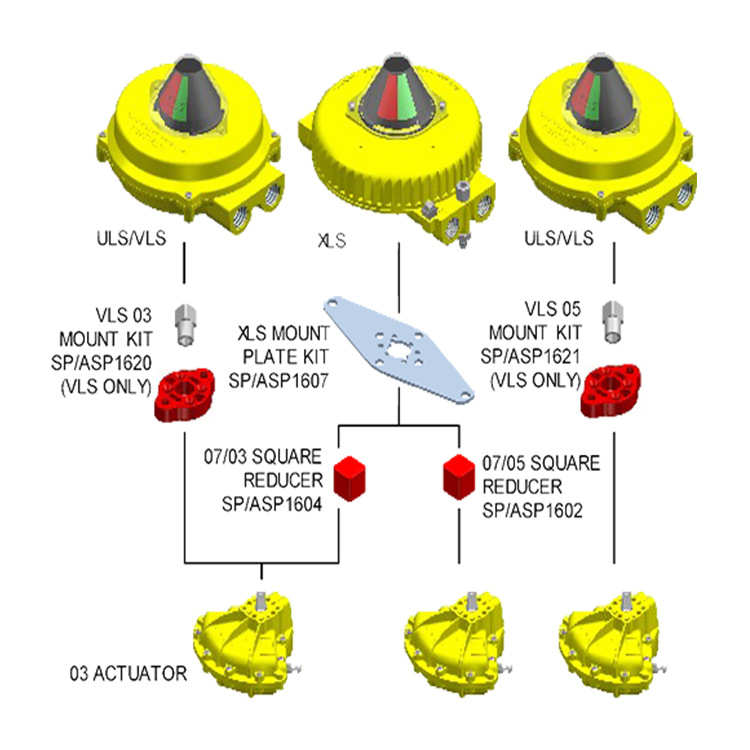

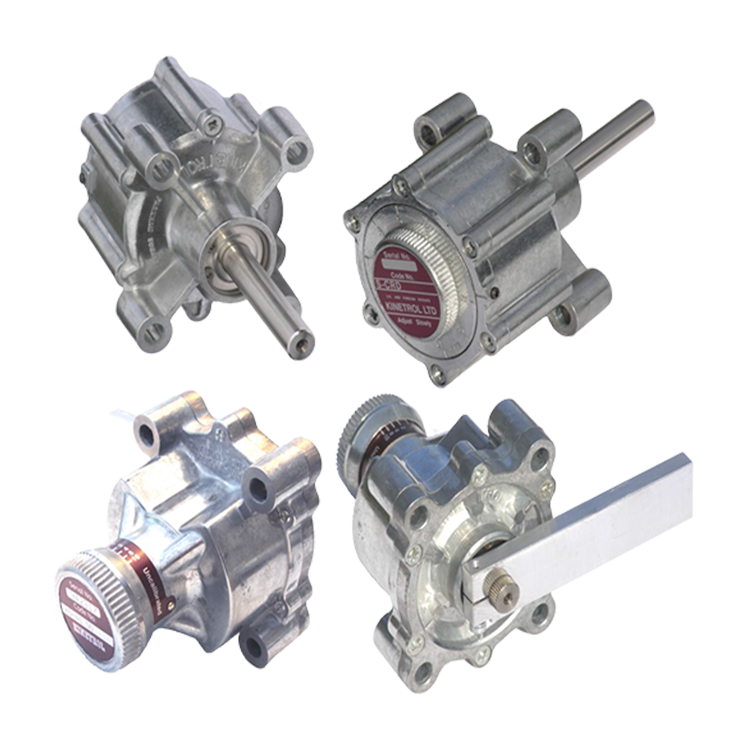

Single-acting or double-acting pneumatic actuators all have high reliability. Since their structure is very light, they work very comfortably. Operating costs are also very low while running. They only cost slightly more in terms of initial setup. Different actuators can be selected according to the shape of the valves or cylinder characteristics.

An absolutely reliable and professional company should be consulted for these actuators, which are needed in industrial systems and in environments with explosives. However, such a company can help you and support you with the actuator you really need. You can contact our company to get information about actuator selection, general features, single or double-acting, piston or cylinder types.

TR

TR