What is the Positioner?

The positioner applies air pressure to determine whether the valve is in the correct position. This positioner is mounted on actuators. Positioners evaluate the control signal coming to the valves and bring the valve to the opening percentage.

It is not possible to determine whether the valve is in the desired position without a positioner. For this reason, it is necessary to use a positioner. Positioners are used especially with 0.2 to 1 bar pressur when friction and differential pressure in the diaphragm chamber cannot be met.

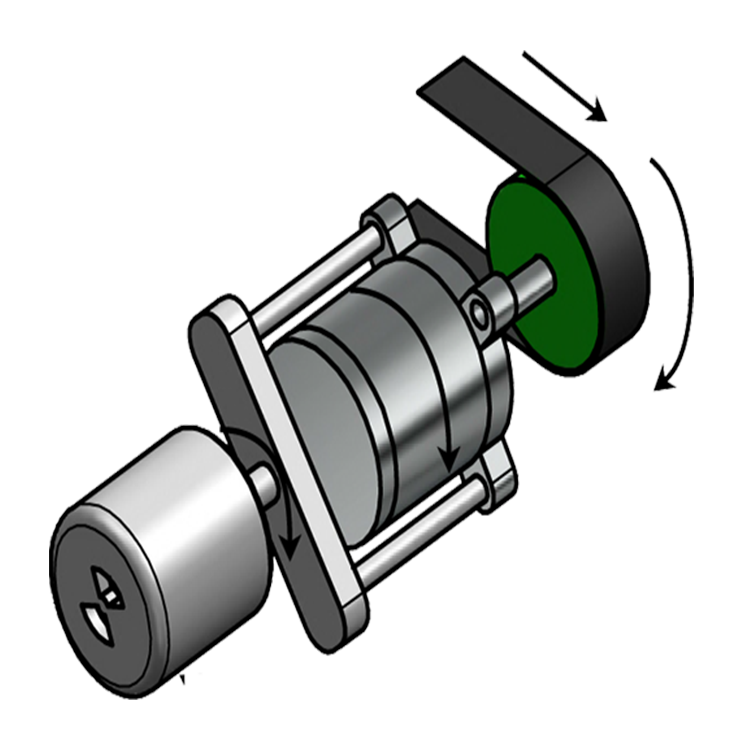

How Does a Positioner Work?

The positioner establishes a linear relationship between the signal input pressure and the control valve. The positioner can be used as a positioner or as a signal amplifier or amplifier. Some positioners can be used as electro-pneumatic transducers.

To operate the positioner it is necessary to attach it to the yoke of the actuator. A feedback arm is connected to the actuator shaft to monitor the valve position. Using high air pressure on the actuator ensures that the positioner reaches the correct position.

What is a Pneumatic Positioner and How Does It Work?

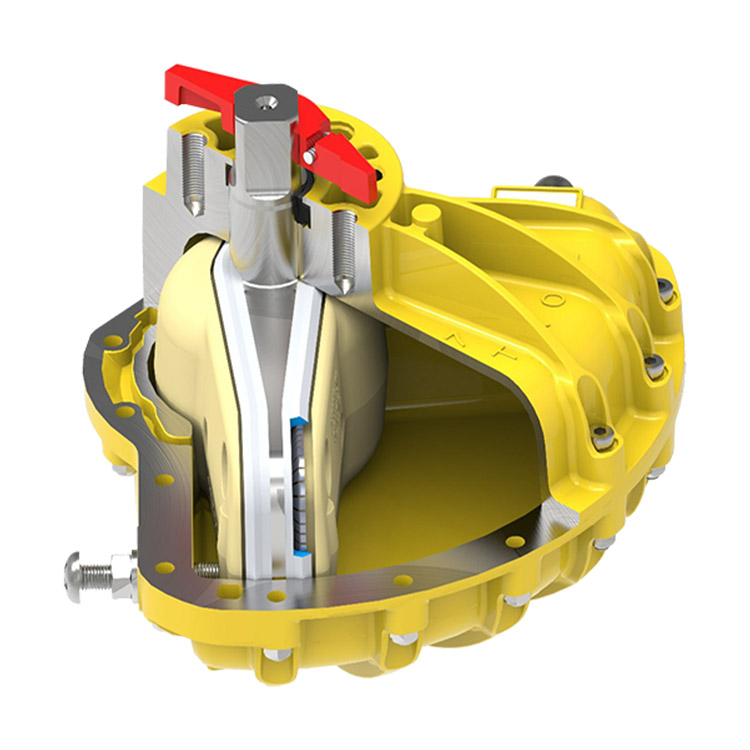

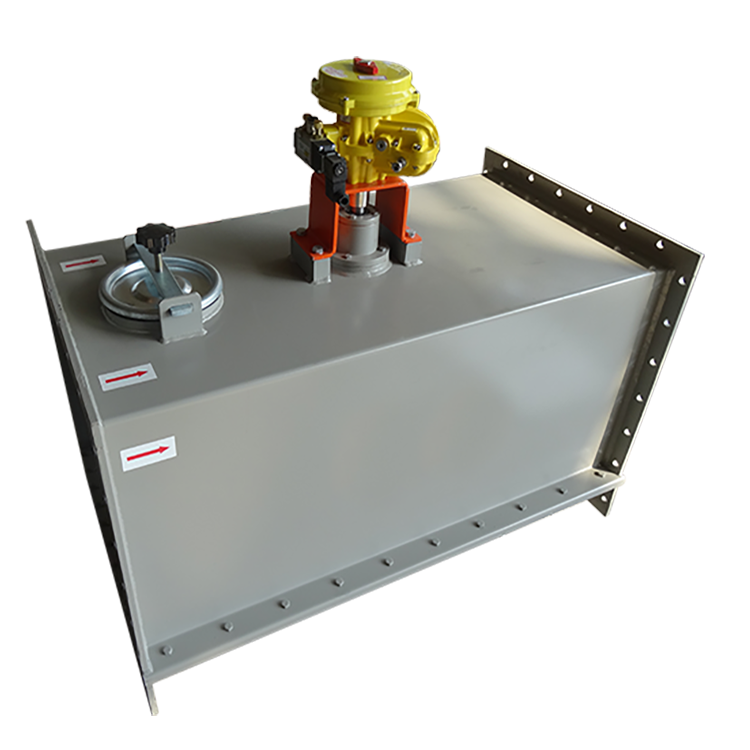

The pneumatic positioner adjusts the opening of the valve according to the pneumatic signal from the control device. The signal is received and sent from the pneumatics. It is explosion-proof. Considerable force is required if you want to turn off the pneumatic positioner.

The pneumatic positioner has a body made of solid aluminum. It has an anti-corrosion surface treatment and valve instrument panel. Pneumatic positioners have a manometer so that the pressure can be monitored. Pneumatic positioners are used with linear air actuators. Pneumatic positioners rotate the control valves to position correctly.

Pneumatic positioners have a pneumatic converter that proportionally converts the control signal from the input to the pneumatic output. In this way, the outlet is fed to the actuator that controls the valve position and flow. Zero and span settings are made. The positioner can be converted into a single-acting and double-acting system. If it is desired to be transformed into a single-acting system, pneumatic positioners are attached to pneumatic control valves.

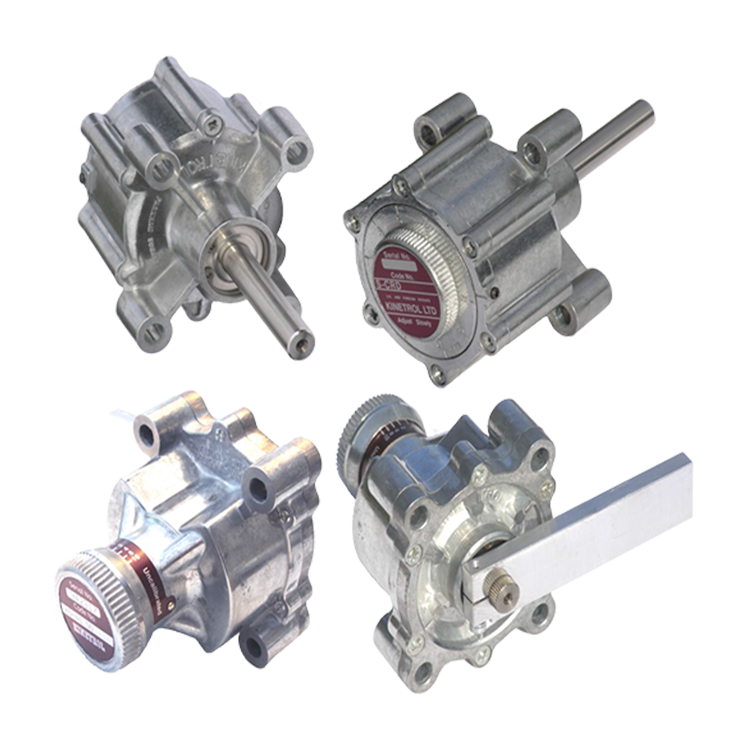

What are the Features of Pneumatic Positioner?

The pneumatic positioner ensures a good reaction demonstration. These types of positioners are easy to maintain and require little maintenance. The mounting position can be adjusted upon request. Maintenance and repair can also be done by some factories. It has the feature of being precisely calibrated. It has an aluminum body to have corrosion and difficult conditions. It has a pressure gauge and is made of stainless steel.

What are the Performance Properties of Pneumatic Positioner?

Pneumatic positioner changes in performance characteristics according to the pneumatic input signal range, maximum air pressure, signal input/output direction, and ambient temperature. Pneumatic input signal range and maximum input pressure are measured in pounds per inch or psi. Split ranges are generally as follows: 4-10 mA and 12-20 mA, There are two-way, three-way, and four-way splits. Pneumatic positioners have three output types: direct, reverse, and field replaceable.

What are Smart or Digital Valve Controllers?

These types of positioners use digital instead of analog. In smart positioners, the control of the valve can be done more comfortably and easily. For this reason, it is used in more areas. Digital valve controllers are made using fewer mechanical parts. For this reason, it has a longer life than other positioners. These positioners consume less air and energy. With smart or digital positioners, calibration is easy and responses are extremely fast.

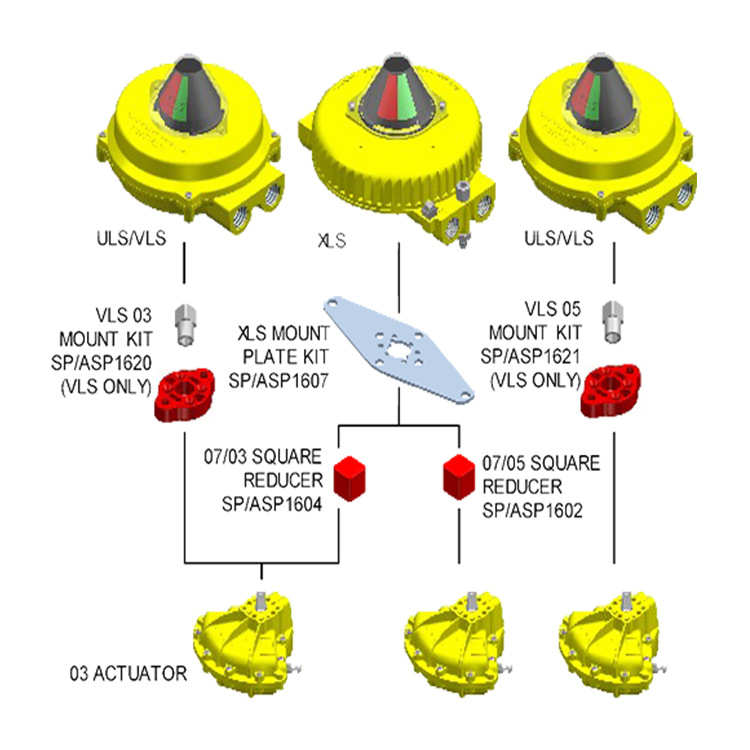

What are the Types of Valve Positioners?

There are four types of positioners; pneumatic positioner, electronic positioner, electro-pneumatic positioner, and digital positioner.

- Electric Valve Positioner: Receives and sends the electric signal. There are 3 types of electric actuators. It is in the form of single-phase, three-phase alternating current and correct mind voltage.

- Electro-pneumatic Valve Positioners: This type of positioner is used to convert the control signal from the current into a pneumatic signal.

- Digital Positioners: This type of positioner uses a microprocessor to position and record the valve actuator. They are very sensitive posers. Uses less air than analog positioners.

- Pneumatic Positioners: This pneumatic positioner receives a signal and sends this signal.

When to Use Positioners?

The positioner is used when valves need to be modulating correctly. We can also use the positioner when we want to speed up the response of the valve. Positioners use high pressure to adjust the valve position. For this reason, this high pressure is used in conjunction with the booster when the actuator and valve need to respond.

Positioners are used in packaging applications where valve friction causes undesired hysteresis. The positioner is used when the actuator of the systems whose actuator is not linear is desired to be made linear. If the change in the pressure difference in the fluid causes the position to change, the positioner can be used at these times.

TR

TR