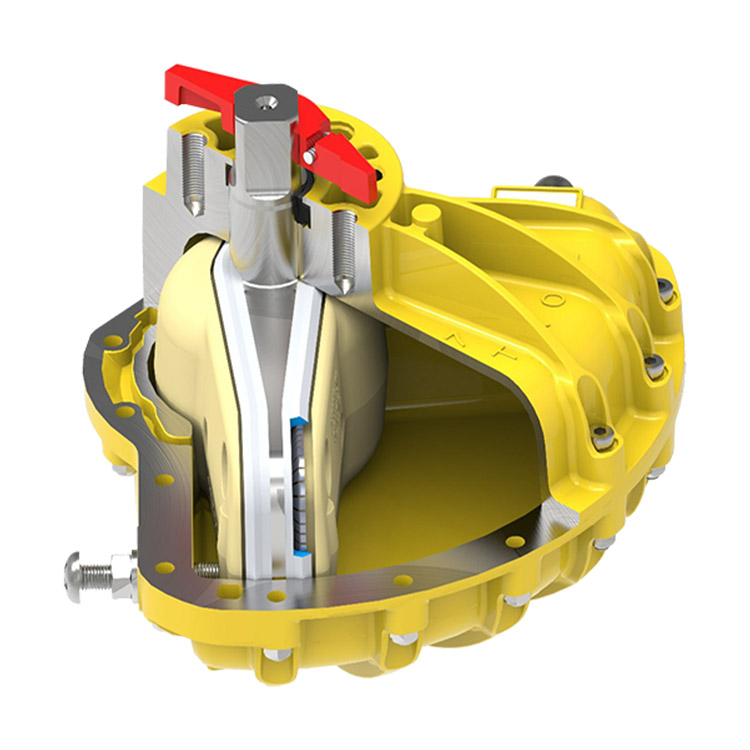

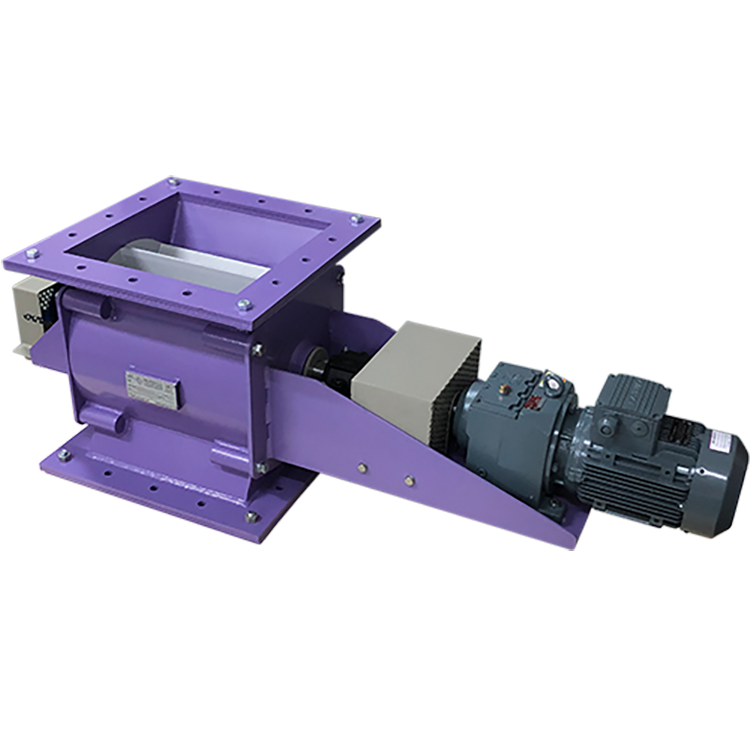

The rotary valve is also called an airlock. Rotary valve is one of the most important parts of a type of transmission arrangement called pneumatic. This part controls the flow of small and barely distinguishable materials such as dust by various methods. Rotary valve play an active role in the regular operation of the product it is in.

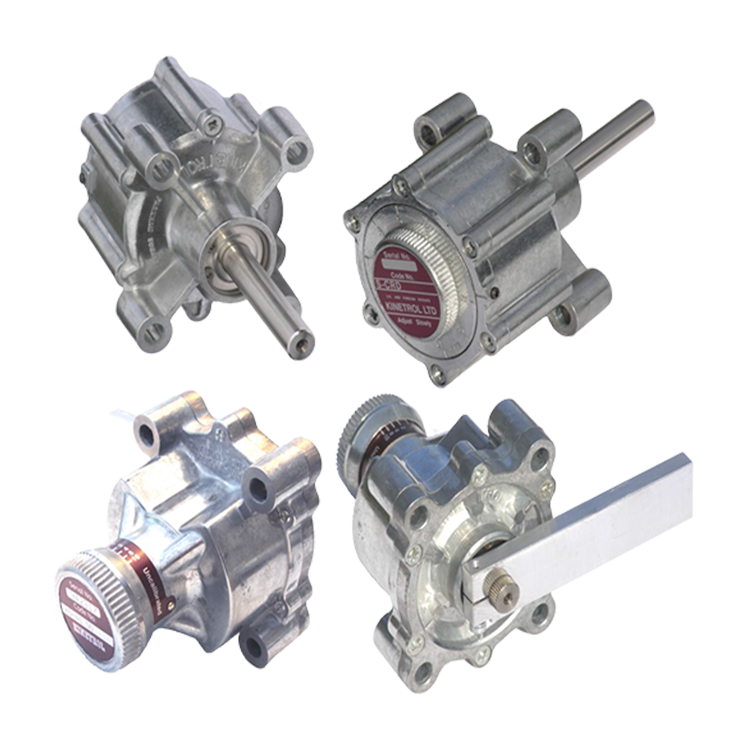

The rotary valve has several types. The existence of various nomenclatures is a result of this. In addition, rotary valves can be used in different areas of use. The rotary valve you will use varies according to the area of use. When you do the necessary research, you can easily find which rotary valve will be suitable for your area of use.

Which Areas Is Rotary Valve Used In?

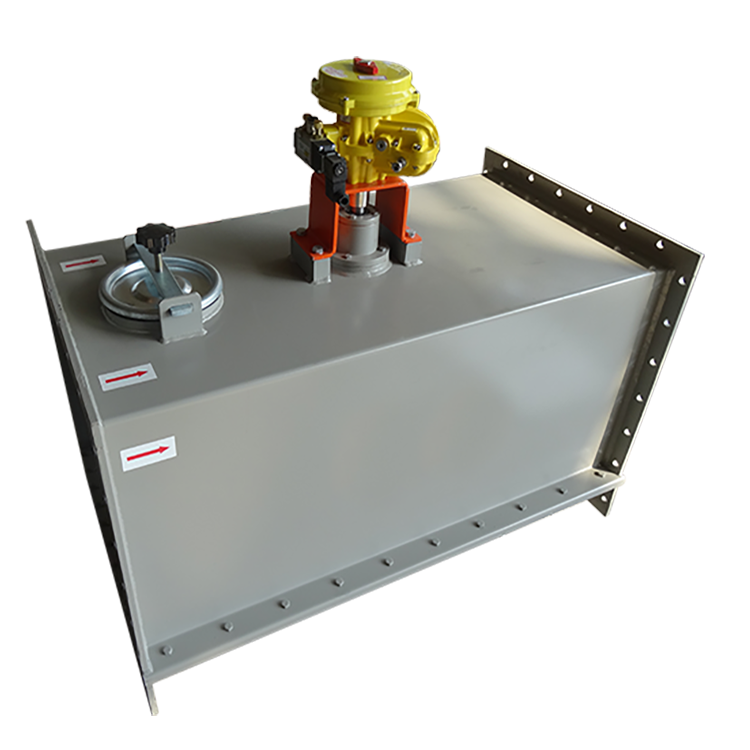

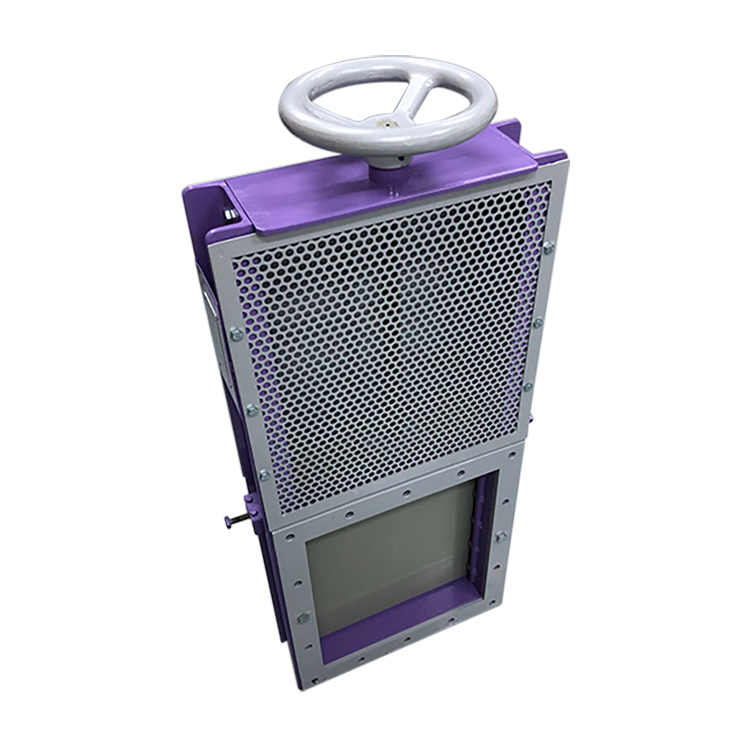

One of the usage area of the rotary valve is for storage. It ensures that the transportation and unloading processes proceed in a controlled manner in areas such as silos and bunkers in the storage area. If you are aiming to unload a product in the warehouse in a controlled manner, the rotary valve is an equipment that helps you in this regard. You can transfer your products to materials such as mixer, screw conveyor and spiral thanks to the rotary valve.

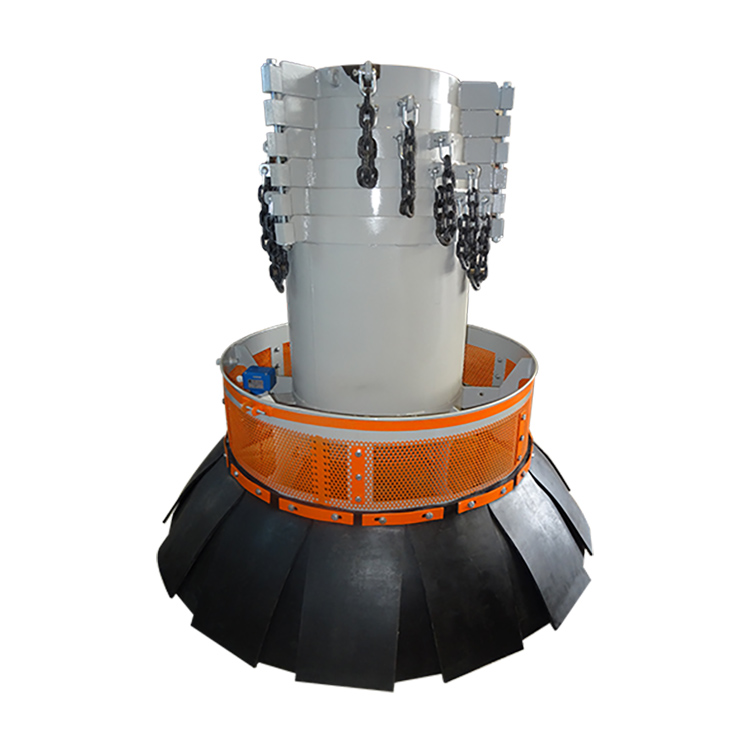

Cyclone is among the usage areas where rotary valve play an active role. When you transfer your product to the cyclone with vacuum and pressure, the rotary valve plays an active role in ensuring that the product is discharged from the cyclone. Rotary valve is also used in filtering applications. In this application, materials such as ash and sawdust are removed from the filter.

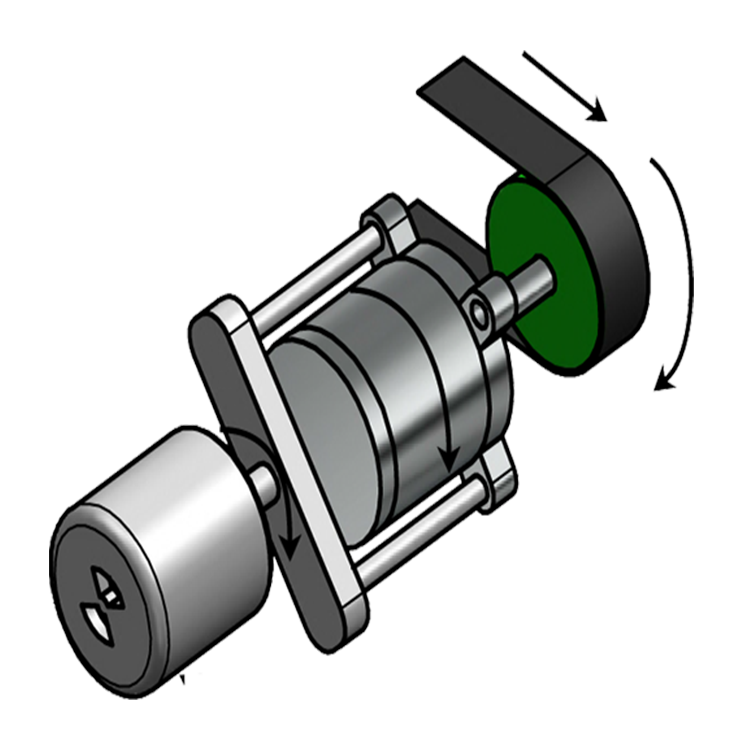

Dosing method is one of the areas where rotary valve is used frequently. The different ratios of solid products can be easily adjusted by the rotary valve. The rotary valve’s role is very important in the field of pneumatic conveying, which we mentioned at the beginning. It is possible to transport the material in the pipelines wherever you want, thanks to the rotary valve. In this way, we can say that you will not have any difficulties in transporting the product on the transport line.

TR

TR