Pneumatic Systems and Their History

Pneumatic systems date back to 2500 BC. The pneumatic system used in these years was called an air blower. The pneumatic system has also started to be used in the mining sector. The pneumatic system is derived from the word Pneuma, which means wind in ancient Greek. On the one hand, it also means spirit. In ancient times, pneumatic systems were used to provide the movement and control of systems operating with gas pressure.

Compressed air was the first type of energy used by ancient people. Air has been perceived consciously and studies have been made for this. The fact that pneumatics entered the field of application as a systematic force dates back to the 19th century. Those who noticed and researched compressed air started to make hand tools using it. First of all, drills, locomotives, and similar power systems were made and became widespread.

Compressed ambient air was used in pneumatic systems in the early days of the realization of this power. However, as time progressed, some gases started to enter the field of the pneumatic system, and nitrogen and carbon dioxide gas were also used in the system. While air gas does not harm human health, nitrogen and carbon dioxide may have some harm.

What is Pneumatic System?

A pneumatic system is simply to operate mechanical systems with compressed air. Generally, ambient air is also used in pneumatic systems. The pneumonic system is activated by activating the ambient air mechanically. Although different gases are used, not all types of gas should be used. For example, because it is a flammable gas, pure oxygen causes great harm to people when compressed.

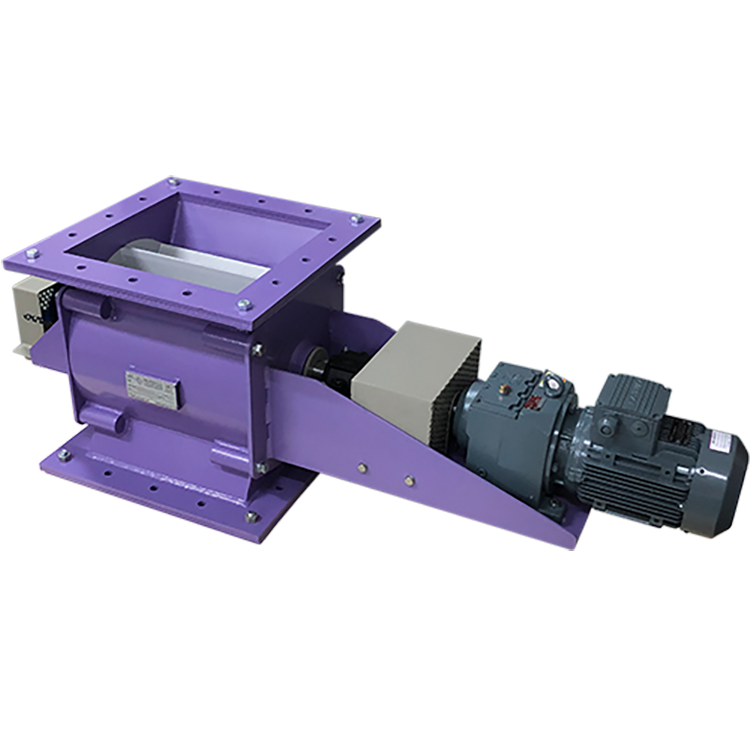

Each gas has its characteristics and therefore may not be included in the pneumatic system. Usually, the ambient air used has a thrust when compressed. Thanks to this force, mechanical mobility is created. Compressors are used for air pressure and stored in air tanks.

What is the Example of a Pneumatic System?

Its pneumatic system is the most visible example of a balloon. Take a balloon in your hand and inflate it to a certain size. In this way, you will be compressing the air in the balloon. Then release the mouth of the balloon you inflated. The trapped air will instantly be activated and the power will turn into energy. With the release of this energy, the balloon moves. Pneumatic energy is just like that.

Where is the Pneumatic System Used?

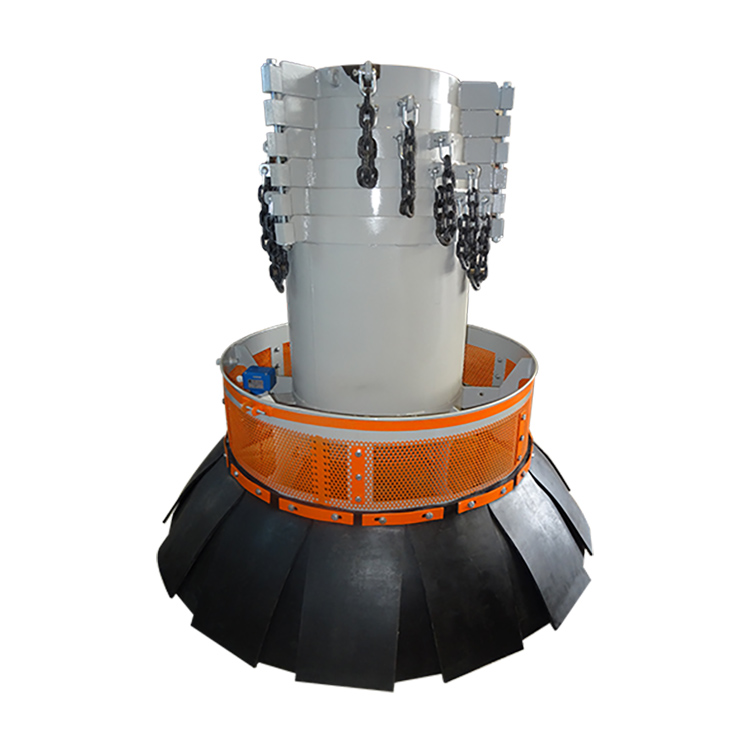

The pneumatic system is used everywhere in the industrial field. Robotic applications and automation systems are examples of sectors where the pneumatic system is used. In addition, the pneumatic system is used in cleaning, painting processes, filling, packaging machines, assembly lines, food industry, work machines, motor vehicles, textile industry. This system is also used for the movement of robots in human form.

What are the Advantages of Pneumatic System?

The pneumatic system brings many advantages along with its use. Generally, the use of ambient air in the pneumatic system minimizes the risk of ignition and explosion. Using the pneumatic system is very economical compared to other systems. The construction of the pneumatic system is simple compared to other systems. It is easy to install, easy to install.

The pneumatic system is more durable than other systems. It does not need any auxiliary staff for recycling. The air used can mix into the atmosphere again, and there is no harm. The pneumatic system has a high working speed and is economical. The strength of the desired energy can be adjusted. The pneumatic system does not need any liquid.

What are the Disadvantages of Pneumatic System?

Pneumatic systems have some minor drawbacks. One of these disadvantages is the noise and the need to process the air. Some of the disadvantages of the pneumatic system are the cooling in the systems due to the effect of air, the limited power transmitted to the pistons, and the loss of energy needed for air compression. Since ambient air is used in pneumatic systems, a lot of noise occurs. There are silencers to suppress this, but silencers partially prevent the noise.

What Are The Components Of The Pneumatic System?

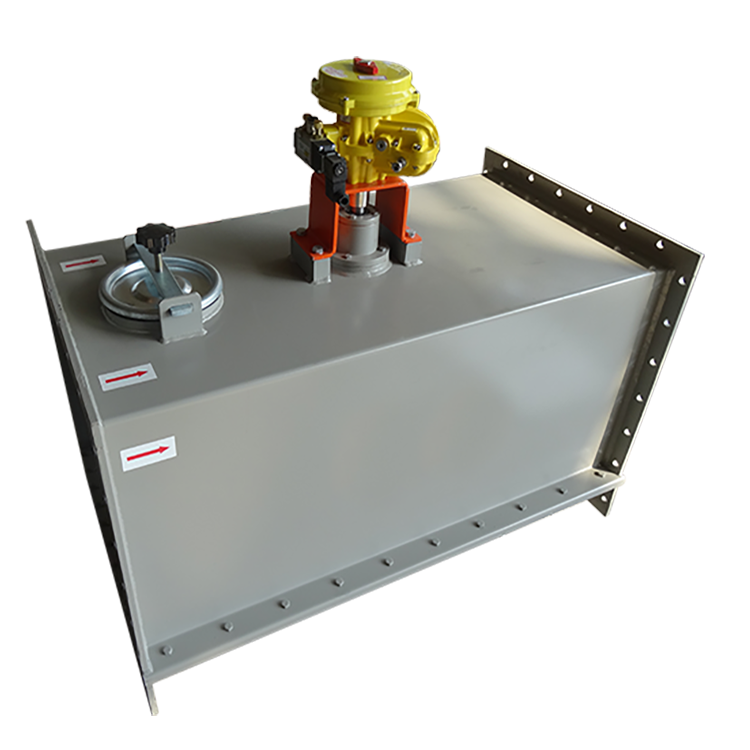

The pneumatic system needs some components to work. The first of these components is the compressor. Compressors are used to produce compressed air. In this way, the system is operated with compressors. The ambient air must be clean and dry for the compressor to produce air.

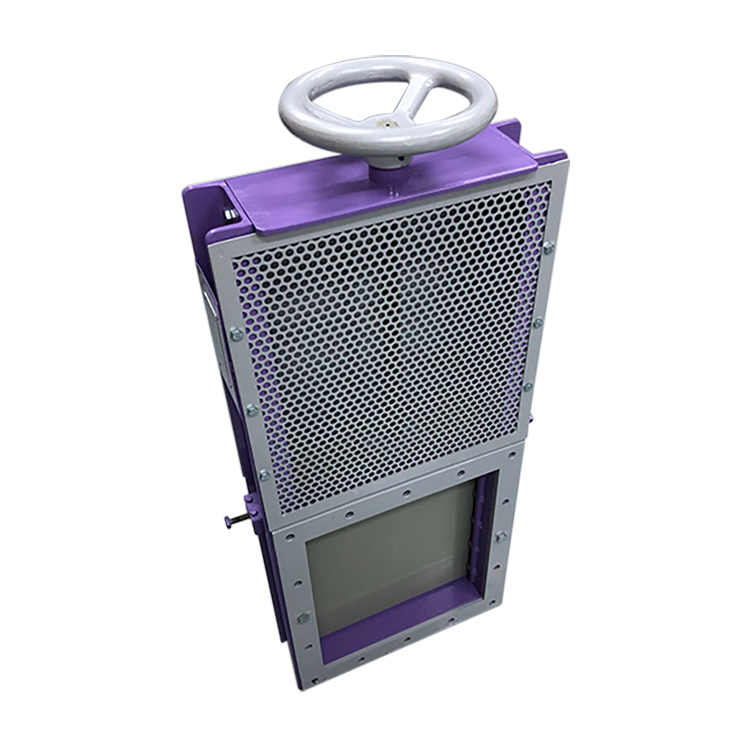

For this, the process of filtering, lubricating, and regulating the air is needed. This process is called the air preparation process. There must be an emergency stop button to control the machines in the pneumatic system. Another component used in pneumatic systems is the regulator. Thanks to the regulator, the air pressure is controlled.

TR

TR