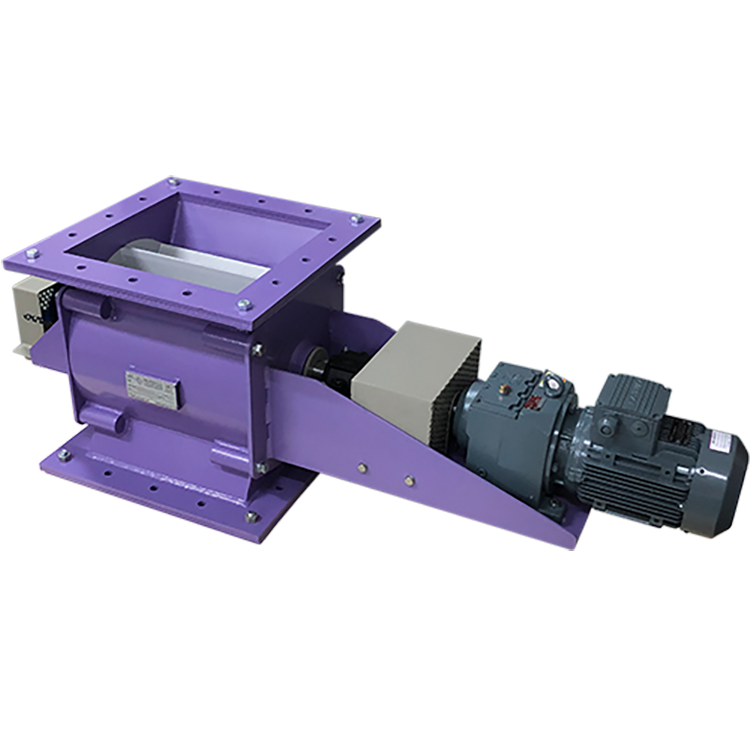

Screw conveyors used in the field of mechanical conveying are generally considered to have a difficult use. However, Screw conveyor are actually among the most economical methods you can use in the field of transportation. When considering the cost, the screw conveyosr is not preferred much in the places where there is a long distance. Those who consider operating costs instead of investment costs prefer to use a screw conveyor.

Screw Conveyors have different usage areas according to feeding types. Some are used for dosing, some for feeding, and some for effervescent function. You should carry out your transportation process in accordance with the capacity of the screw conveyor. If you carry out the transportation process without considering the capacity of the screw conveyor, you may encounter various problems during the work. For this reason, you should pay attention to the capacity – load ratio.

What are the Screw Conveyor Types?

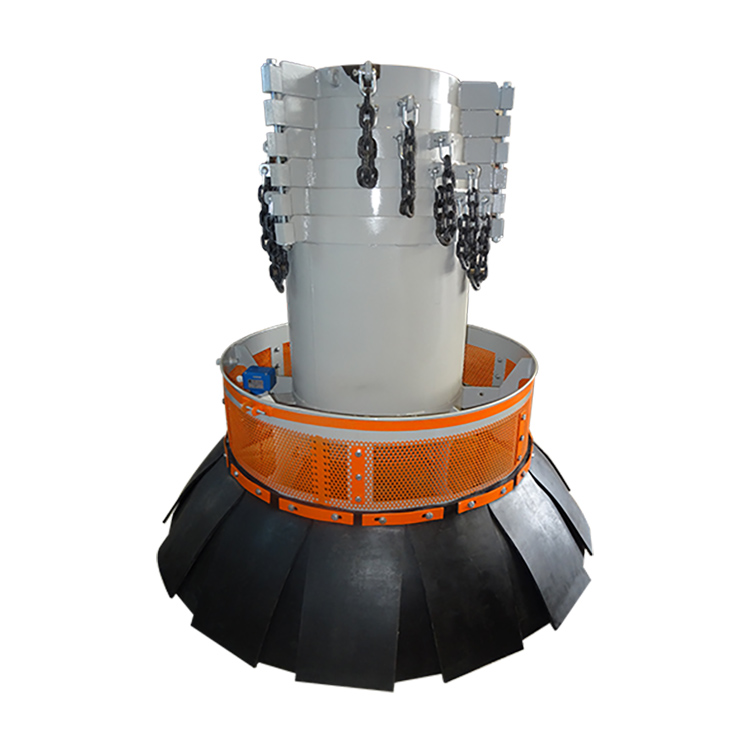

If your place is short, you can use flexible screw conveyors. These screw conveyors have a taker function among the functions we have just mentioned. You can generally use flexible screw conveyors for unloading in bunker areas. The products that you will carry out the transport process will get better efficiency in powder materials. The efficiency of the screw conveyors according to the properties of the product you are carrying. For this reason, you should choose augers suitable for your usage area.

The efficiency of the screw conveyors can be more or less according to many reasons. The product you are carrying, the operator’s use of the screw conveyor and similar factors affect the operation of the screw conveyor. For this reason, it is imperative that you pay attention to some things when using the screw conveyor. People with knowledge in the sector generally recommend flexible screw conveyors in terms of ease of use. However, if you do not use flexible spirals carefully, you will experience all kinds of problems.

The increase in speed in the use of screw conveyor may cause the area to exit from the product to close. This closure adversely affects the screw conveyor leaves. The screw conveyor leaves break when negatively affected by this situation. Breakage in the leaves greatly reduces the working efficiency of the screw conveyor. For this reason, you should pay attention to factors such as high speed in the use of screw conveyor.

Advantage and Disadvantage of Screw Conveyor

Screw conveyor convey materials easily. You can transport materials in three different ways, vertical, horizontal and inclined. Unlike other transportation systems, there are multiple inlet and outlet points. The high input and output direction of the screw conveyor is a feature that provides great convenience in factories. You will not have any problem while transporting powder materials.

One of the disadvantages of the screw conveyor is that they cannot carry much product. You cannot easily transport large-sized materials. You will also have difficulty handling corrosive materials. The number of those who prefer not to use it due to such restricted uses as well as the number of those who do not. You are likely to encounter a clogging problem in screw conveyors while transporting adhesive materials.

TR

TR