Different products are preferred according to the usage capacity and efficiency of such systems, which are generally preferred according to their usage areas. Recently, it seems that such systems are preferred in the selection process with different characteristics.

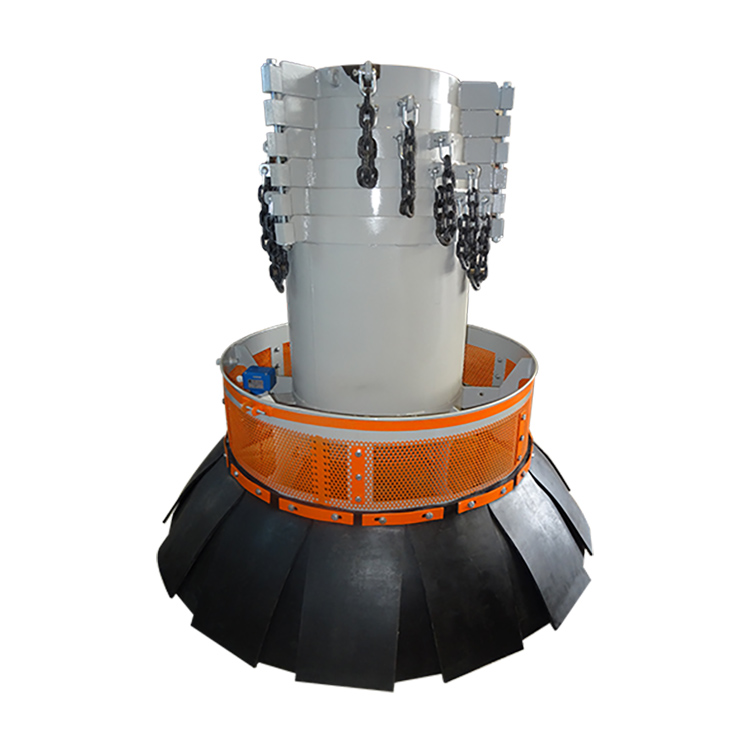

At the same time, depending on the characteristics of the places of use, the frequent use of different qualified products is noticeable. With the usage of such products in industrial areas and different places, industry needs are met. Besides, at the stage of detection and maintenance of flow systems, such systems are often used as a dosing valve.

Where Is The Dosing Valve Used?

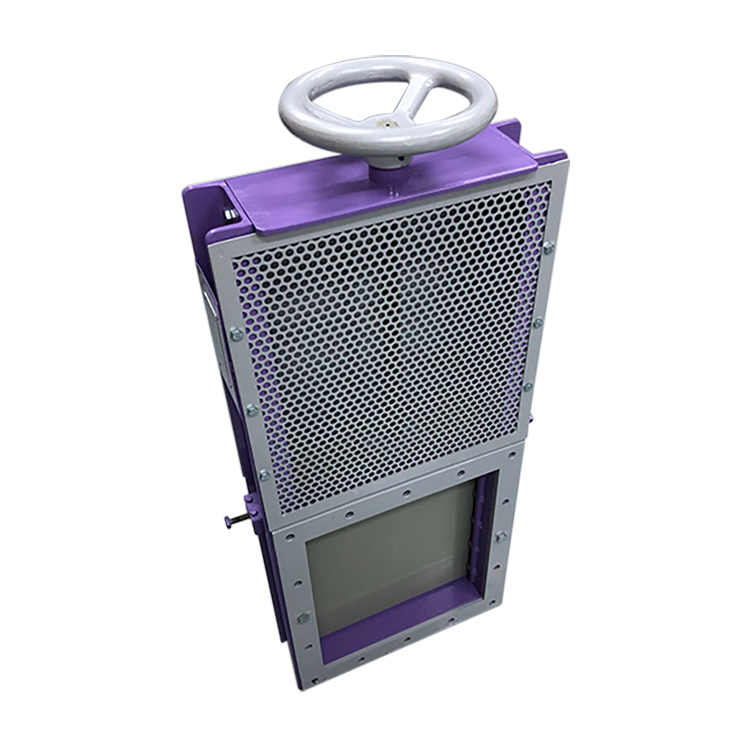

Such products, used in many systems that require flow control, also meet different expectations and are used in the control units of important facilities. It is usually possible to use such products at silo or bunker exits.

It seems that the valves are also used in packaping plant. Thanks to its use in bulk loading facilities, you can ensure that the facilities meet their more qualified energy needs and you can choose the most suitable product for you. It is possible to offer different-sized solutions in various scale feeding systems. Such products are used as dosing flap in-band scale or feding scale systems.

Which Product Is Used Where?

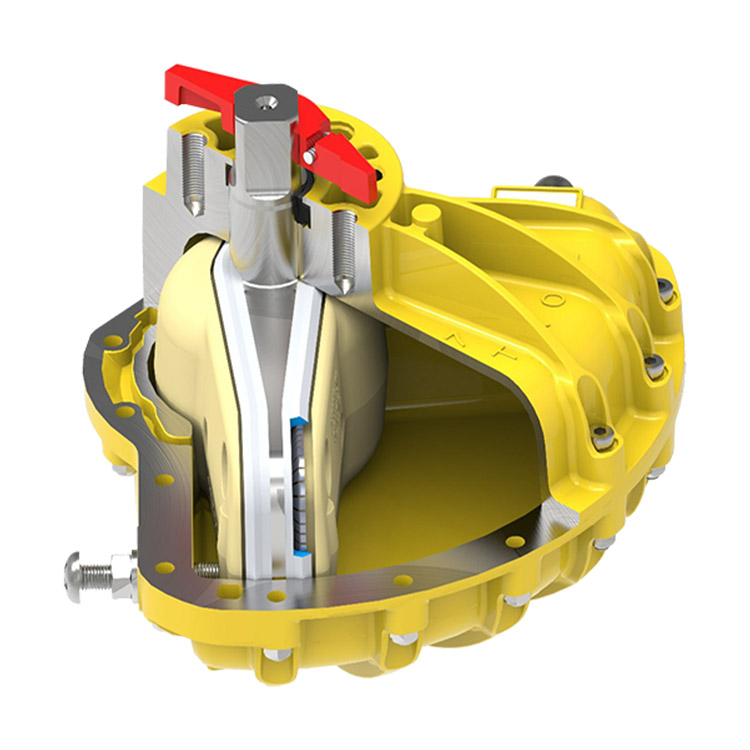

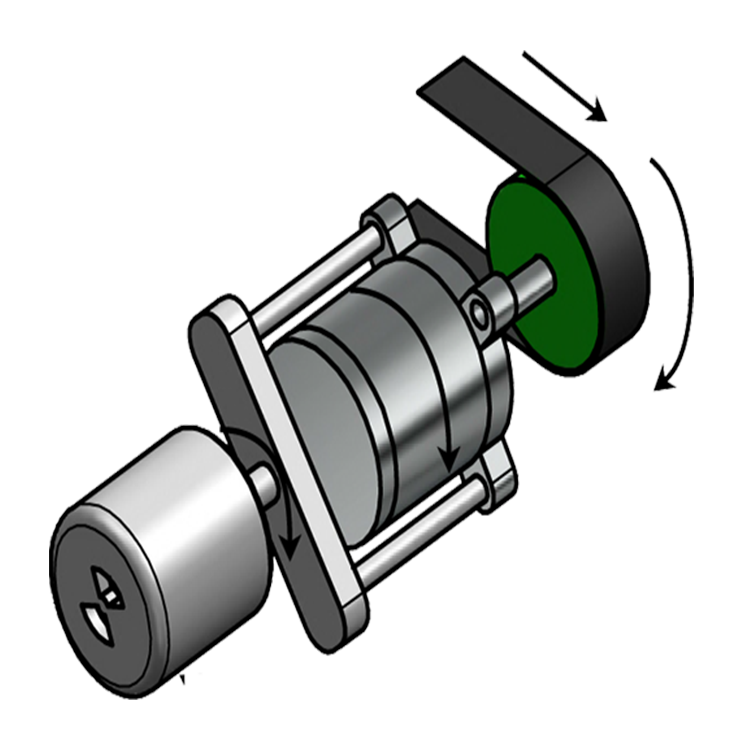

These products, which are used as dosing valves, can be used in all kinds of feeding systems. It can be used in automation-compatible systems that can be operate between 4 and 20 mill amps as a connection to different feed types. It is also possible to use it on different sloping surfaces. Mainly, used in outputs that dosing proportionally between 0 and 90 degrees.

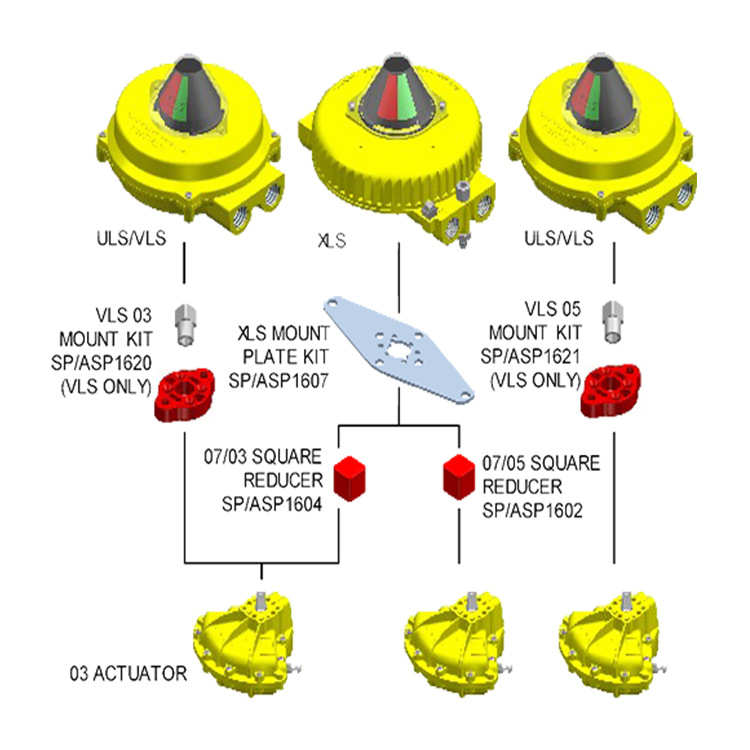

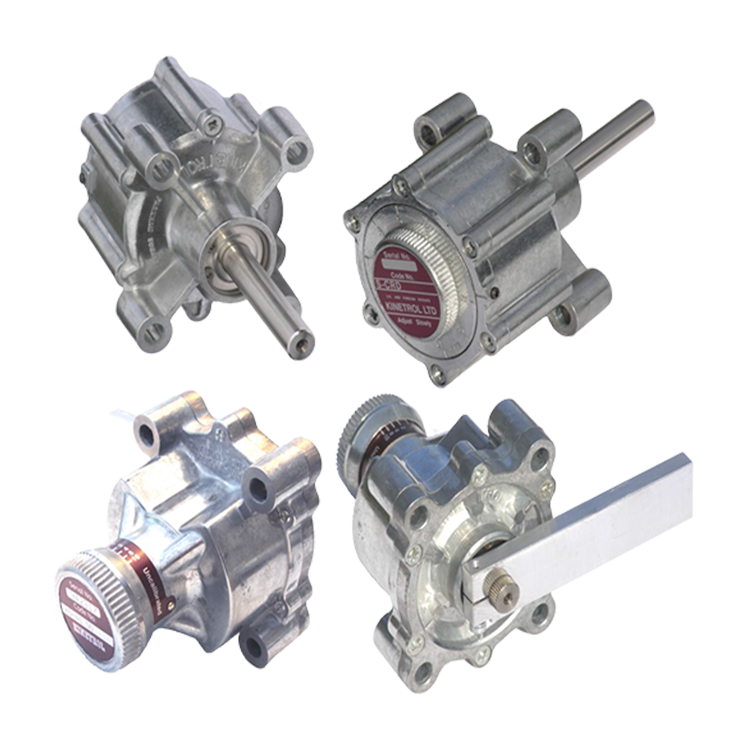

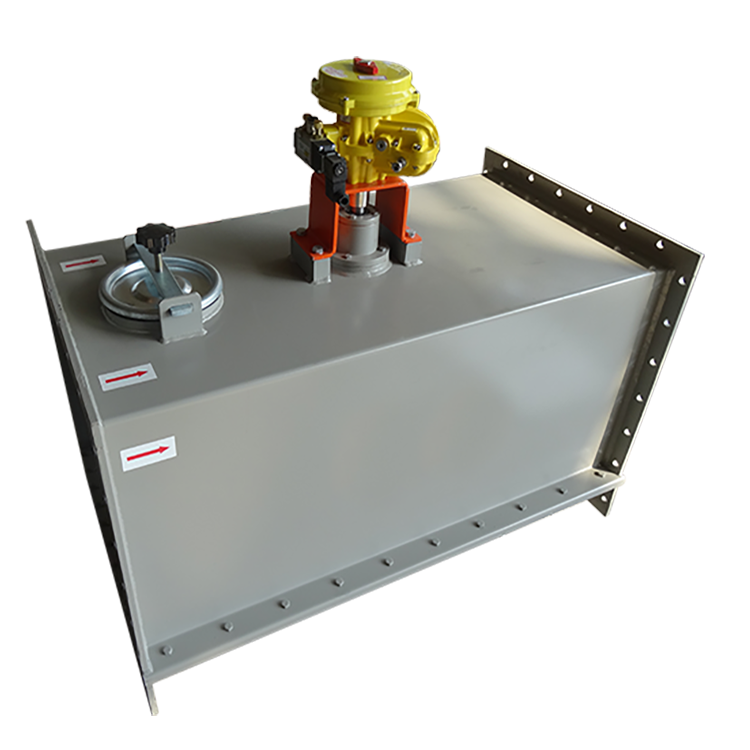

Such systems can stop automatically during power failure. At the same time, maintenance costs are minimized along with the ease of maintenance of such systems. A clean working environment is provided thanks to the seal system inside the dosing valves in places that require sealing. The first point to consider before supplying the dosing valves will be to select the correct drive system and control group. At this point, our company prefers pneumatic drive units of Kinetrol brand products. Also, supplier and manufacturer reliability should be taken into account in terms of ease of maintenance of the valve and sustainable service procurement.

TR

TR