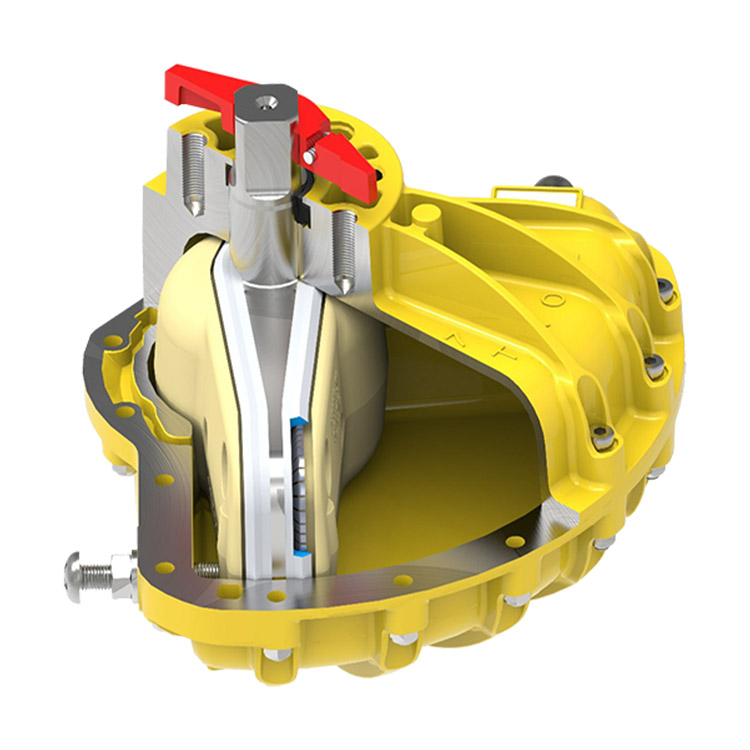

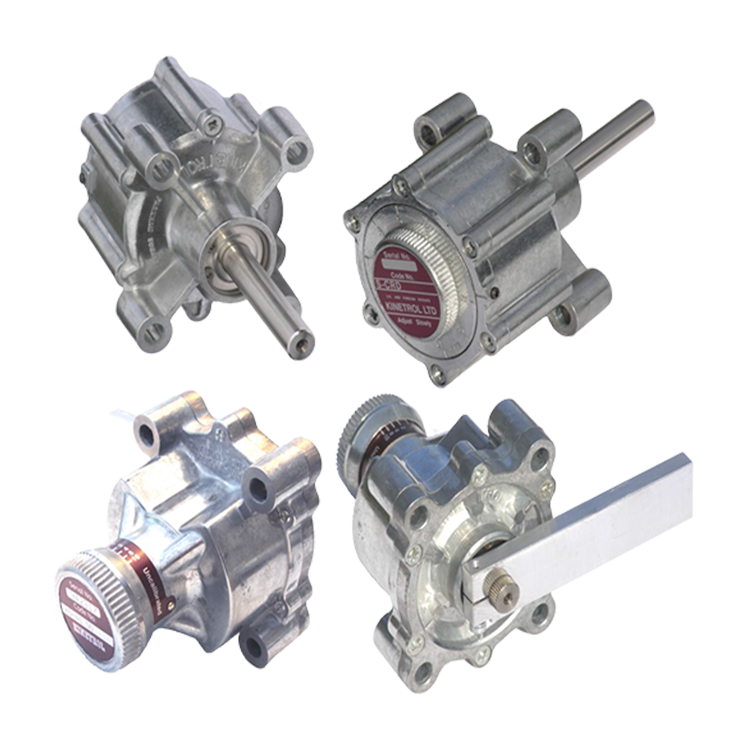

Actuators are tools that work with different forms of energy and control valves and valves. They work by converting the power they receive into mechanical energy. It is generally attached or placed on or on the body of a valve. In terms of energy sources, they are divided into three as electrical, hydraulic and pneumatic.

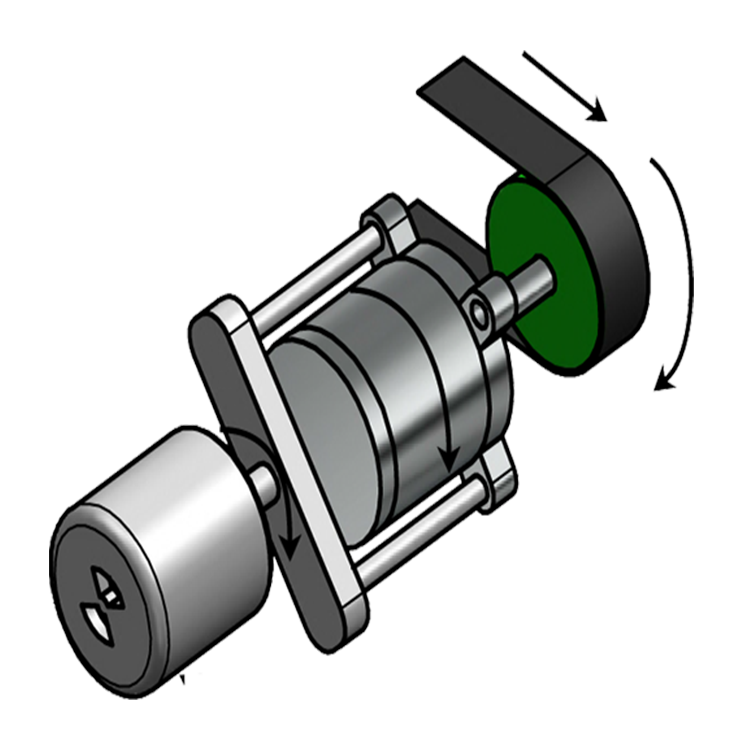

In terms of their movements, they are divided into two type as linear and rotary. The usage area of actuators is quite wide. Actuators are used to control pressure, temperature, level and flow. In addition, they help with jobs such as draining, capping and mixing. Actuator selection depends on where and how it will be used. For example, a pneumatic actuator is definitely needed in a chemical industry where explosives are also present.

Things to Know While Choosing an Actuator

While choosing an actuator, you first look at which type you need to choose, “electric, hydraulic or pneumatic”. Then another important point is what is the moment for opening and closing. The pressure at which the actuator operates and the electricity supply are also important. It is also important where the actuator is to be mounted.

For example, if it is to be mounted on a valve and this valve has a direct connection, the square of the shaft must be measured first. If the valve does not have a direct connection, an interconnection must be prepared. While preparing this connection, the temperature of the environment should not be calculated. Another important issue is whether the actuator should have an on-off or proportional operating principle.

On-Off / Modulating Type Selection

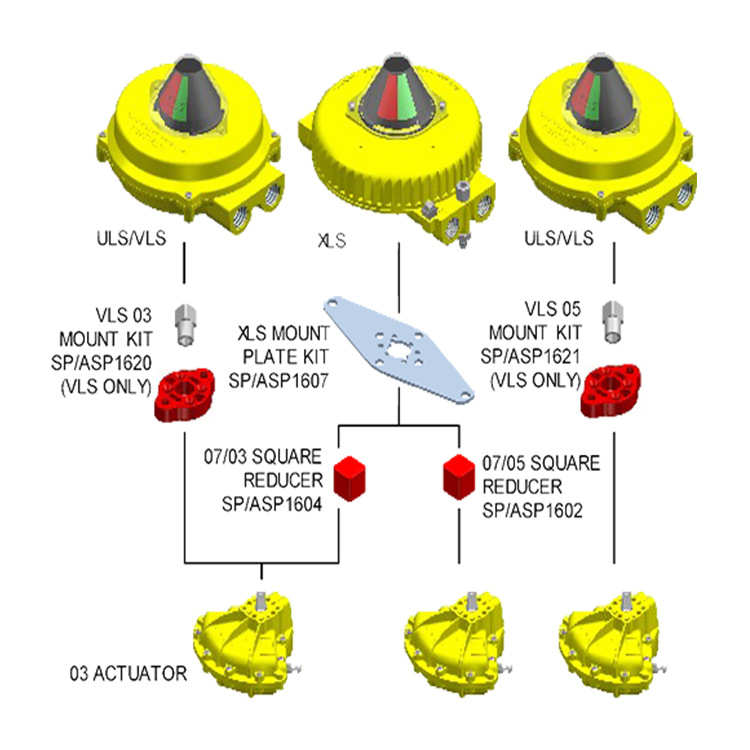

If an on-off actuator is to be selected, accessories that this actuator will need should also be selected. These are generally accessories such as speed adjustment and directional valve, positioner, switch box, conditioner and regulator. Although an actuator with a proportional operating principle will be selected, the type of the positioner must be determined. It is also important whether this actuator requires manual control or not.

The zone in which the system is located must be tested. Selecting the power supply according to the reliability, response time and control distance are other points that should be considered. However, some of the required specifications should also be determined. Finally, it is also important to choose communication sources in accordance with the process. An actuator is selected according to the work done and the working environment.

TR

TR