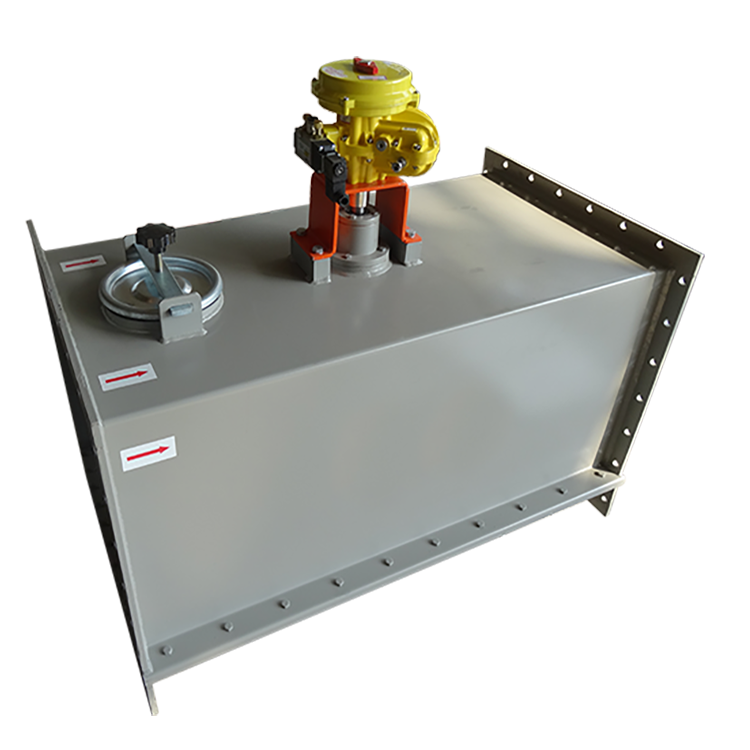

Actuators are systems used in many industrial facilities. They are also required for automation applications. According to the working principle, actuators can be divided into electric, hydraulic or pneumatic. Unlike others, pneumatic actuators work with a compressor. They may be slightly more expensive than other systems due to the need for a compressor to be

Author Archives: Mor Endüstri Ltd.

Generally, actuators operating with compressed air or various gases are called pneumatic actuators. Actuators, have a very important function in the chemical industry and automation applications, are divided into electric, hydraulic and pneumatic. According to the different characteristics of the application, the correct product should be selected. Pneumatic actuators are one of the most advantageous

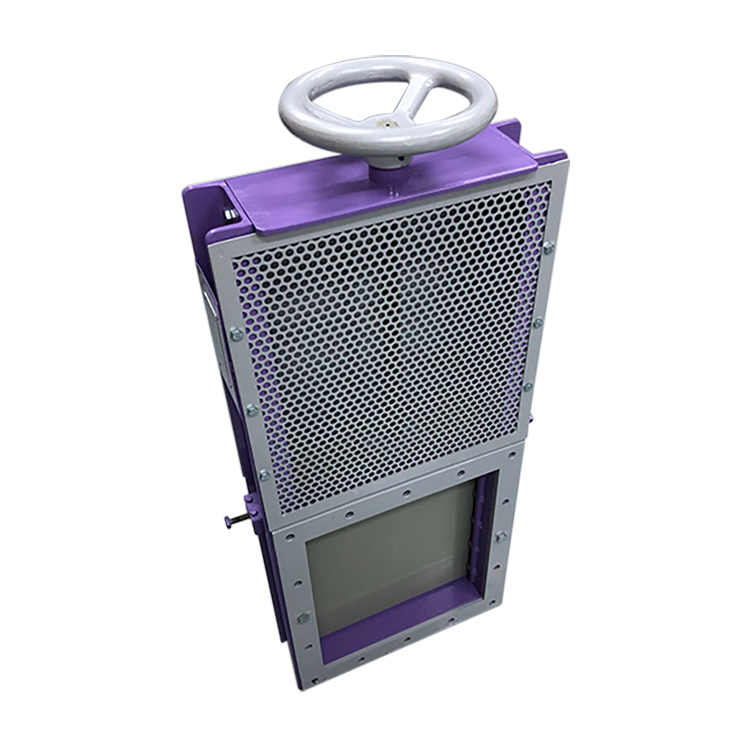

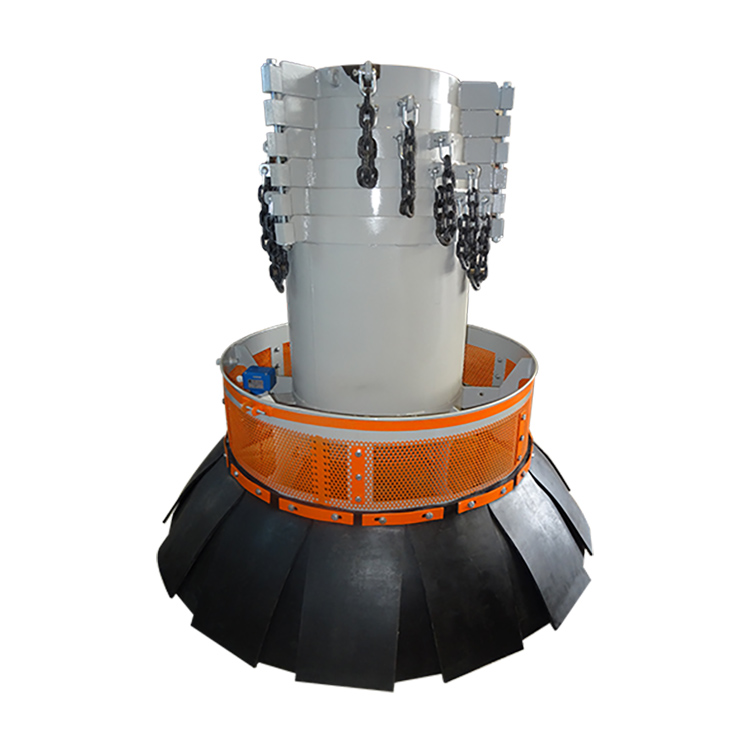

Pneumatic systems can be used in many areas. As a short description, these systems are mechanical systems that can work with compressed air or various gases. The most basic feature of pneumatic systems is that air and gases can be changed and controlled. Plug-ins such as valves in the systems allow the pressure to be

IP protection codes and levels are an international standard. IP stands for international protection code. It is a standard that will be used to test how much all electrically operated tools and equipment are against external factors. This code is given to all electrical products. The IP code is used to indicate that it will

Explosive and flammable materials can be found in many industrial facilities. Various precautions should be taken against any explosion and fire possibility for working and occupational safety. The ATEX certificate is an internationally valid certificate proving that these measures have been taken. The articles of this certificate primarily contain some rules and precautions to prevent

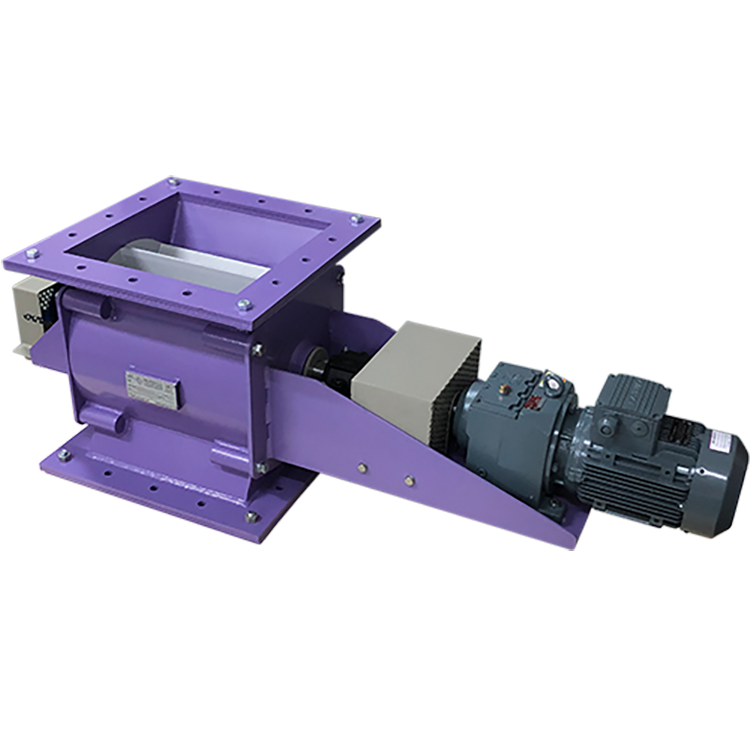

The dosing valve plays an important role to control the fuild. Dosing means adding a new substance to raw material. The dosing flap is a part used in many different places and control units according to its usage and purpose. Bunker and silo exits are among the places where valves are used the most. Packaging

Solenoid valves can be described as electromechanical valves used to control the passage of some fluids. These fluids can be various gases, oil, air, water, and steam. A solenoid valve is generally used for fluids with a temperature of fewer than 150 degrees. They are also electromagnet-controlled valves. The valve both controls the passage of

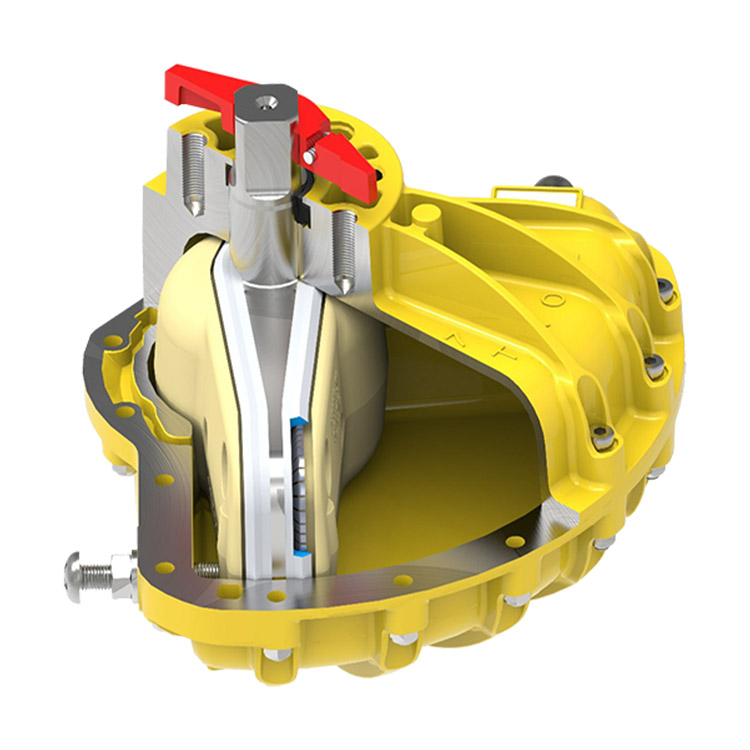

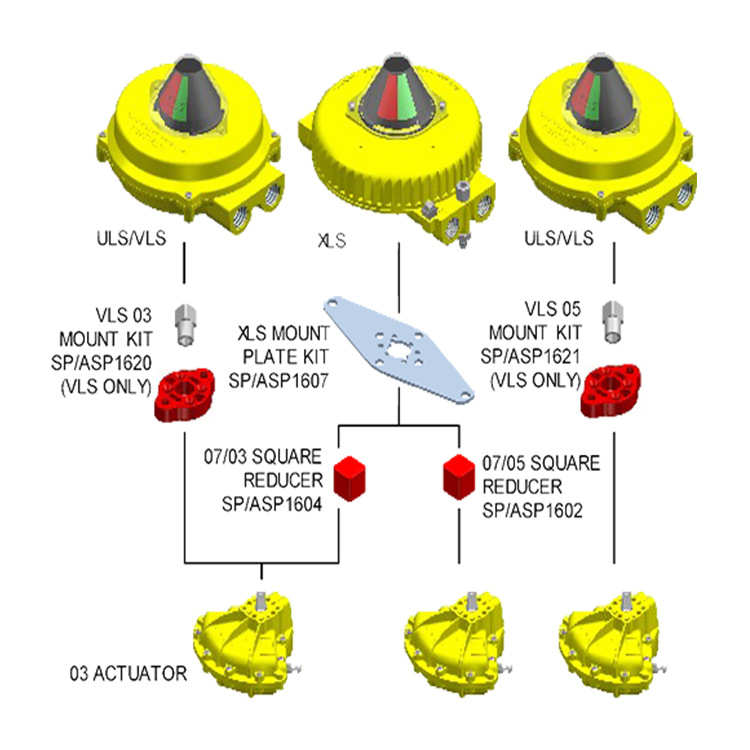

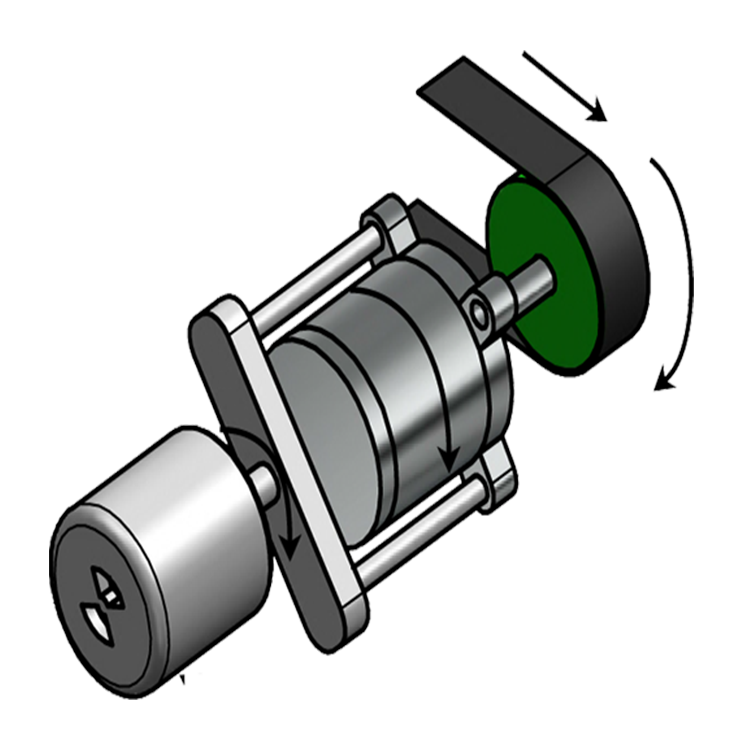

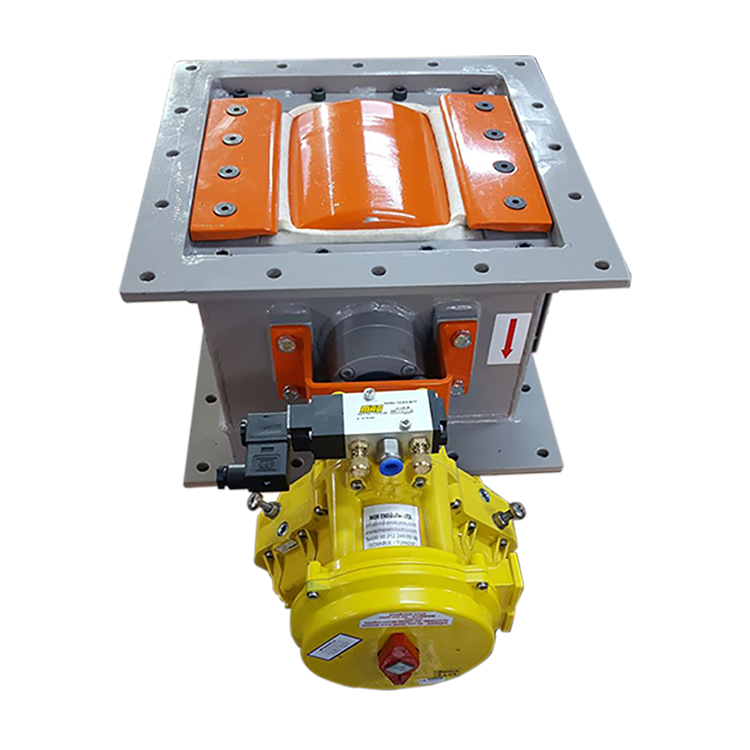

Pneumatic actuators are types of actuators working with compressed air and gases. According to the working principles, there are either linear or spherical ones. There are also a variety of double or single-acting actuators. Pneumatic actuator selection is made according to which area to be used. Valves are also one of the most important parts

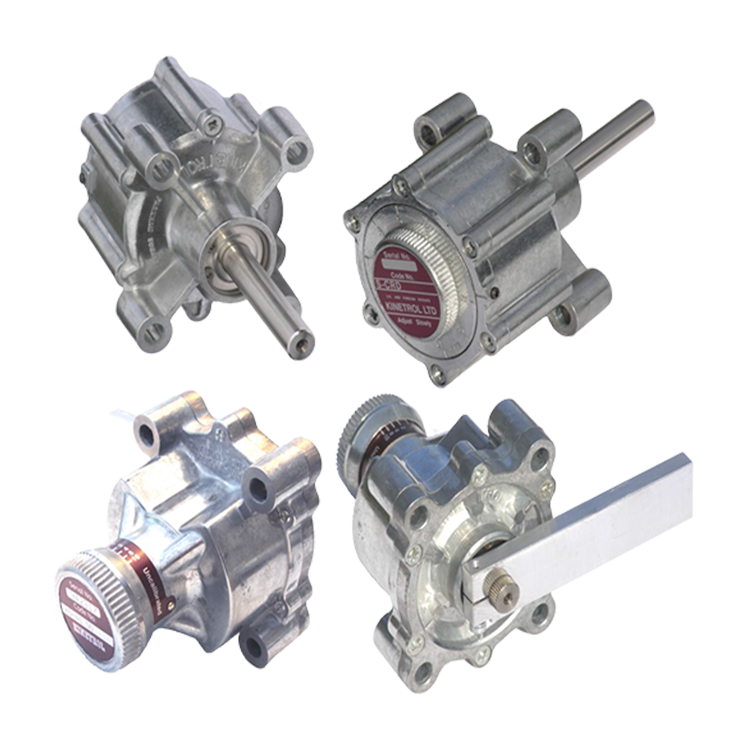

Actuators are mechanisms that are used with valves and convert the energy they use into mechanical energy to move some devices and objects. Actuators, which can be used in almost every field, are mostly used in the applications of automation systems and in the chemical industry. Pneumatic actuators work with air and gas pressure. They

Actuators are tools that work with different forms of energy and control valves and valves. They work by converting the power they receive into mechanical energy. It is generally attached or placed on or on the body of a valve. In terms of energy sources, they are divided into three as electrical, hydraulic and pneumatic.

TR

TR